Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Which Cracks In Concrete Can Be Repaired?

Article content

1. Causes of concrete cracks

2. How to repair concrete cracks?

3. Bridge crack repair method

Causes of concrete cracks

Contrary to popular belief, concrete is one of the most durable building materials, and it can crack due to many factors. In some cases, the existence of cracks can cause unpleasant factors, so it is recommended to eliminate the cracks in a short time.

But first, you need to understand what causes the concrete cracks. There are several reasons for this to happen:

An error occurred during the pouring of the concrete structure;

Severe temperature drop;

Shrinking buildings;

Weak tendons

Soil expansion

Exposure to salt

Mechanical damage.

In some cases, cracks in concrete are considered safe for structural integrity. Usually these are horizontal cracks with a maximum width of 0.4 mm. When the corrosive environment affects the concrete structure, the requirements become more stringent-up to 0.3 mm.

How to repair concrete cracks?

Various materials are widely used for this purpose:

Cement sand mixture;

Sealant

Epoxy resin

Liquid glass

Self-expanding line.

The selection of the composition should take into account the width and location of the crack, the degree of hardening of the concrete and the tendency of the defect to expand.

In the case of vertical cracks, the thickest mixture of self-expanding cords and the listed cords is advantageous.

Bridge crack repair method

Injection. For this purpose, holes are drilled in the direction of the crack, and then the holes are filled with a suitable compound. The edges of the cracks are glued together, so no further crack propagation occurs.

Shotcrete. In this case, patch the crack itself with a repair agent, and then spray another layer of concrete mixture on top.

Seal. A sand concrete composition filled with polymer additives in defects is intended to improve surface adhesion. From above, the problem area is torn by a layer of sealant.

In order to repair cracks on the concrete surface, appropriate professional tools are required.

By following the technique for preparing the concrete mixture and the subsequent pouring technique, it is possible to prevent cracks in the concrete. If the future structure will bear huge loads, it is impossible to save reinforcement materials. You also need to study the soil at the construction site first so that its characteristics will not cause trouble in the future. If the concrete is poured at low temperatures, the optimum temperature conditions must be provided to reliably cure the concrete mixture.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

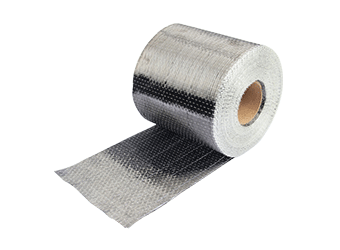

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O adesivo para injeção de rachaduras em concreto Horse HM-120L é um epóxi usado para reparar rachaduras em concreto por injeção. O epóxi tem alta propriedade de penetração. Injeção de baixa pressão de rachaduras em concreto estrutural.