Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

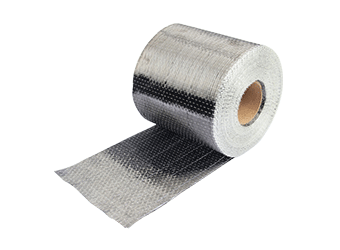

FRP Carbon Fiber Reinforced System

FRP

HORSE's composite reinforcement system is designed, tested and manufactured to provide high-performance solutions and lasting effects. Provide efficient fiber-reinforced polymer (FRP) materials for structural reinforcement and reinforcement of concrete, masonry, and wood structures that need to be repaired or upgraded.

Fiber-reinforced polymer (FRP) systems are simply defined as high-strength and lightweight reinforcement materials formed by combining carbon (CFRP) fibers with polymer materials. The performance characteristics of FRP reinforcement are becoming more and more popular in construction and renovation applications, especially in aging, damaged or overloaded concrete structures.

Compared with traditional reconstruction methods, the main advantage of the FRP system is that it can achieve significant bending, axial or shear strength gains through easy-to-apply composite materials without significantly increasing the weight or mass of the structure.

For decades, steel plate bonding, concrete cross-section enlargement and steel sheathing have been the preferred renovation methods. However, corrosion, adhesion degradation and installation difficulties are consistent challenges that need to be overcome. The resulting transformation usually increases weight, reduces available space, gaps, or both.

In three common situations, FRP has proven to be more economical than traditional reinforcement methods:

Increase the load-bearing capacity of the structure beyond the original specifications or expectations

Seismic reinforcement

Repair concrete structures that have been damaged over time

Features and advantages of FRP materials

In many cases, considering the reduction of preparation and labor costs, FRP is the most economical choice. FRP can usually be installed without stopping the structure.

Economically increase capacity without significant weight or mass

Very high tensile strength

Lightweight and user-friendly installation

Non-corrosive

Low aesthetic impact

Compatible with many finishes and protective coatings

FRP application

FRP has a wide range of consumer, commercial and public sector applications. In the commercial and public sectors, the most common FRP application is concrete reinforcement.

Seismic transformation: shear strengthening, displacement/ductility, life safety

Damage repair: concrete structure damaged over time, aging/corrosion, explosion/vehicle impact

Rated load upgrade: increase live load, new equipment, change use

Defect repair: wrong size/layout, low concrete strength

Explosion mitigation: hardening, progressive collapse

Structure: buildings, bridges, storage tanks/silos, parking structures, docks and piers, underwater structures, tunnels, pipelines

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

Boa impregnação, adesivo de fibra de carbono HM-180C3P para aplicação de fibra de carbono em estruturas para reforço estrutural

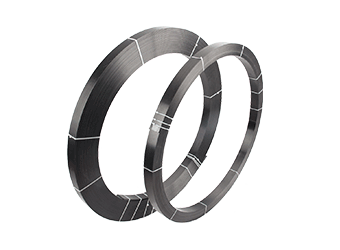

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.