Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

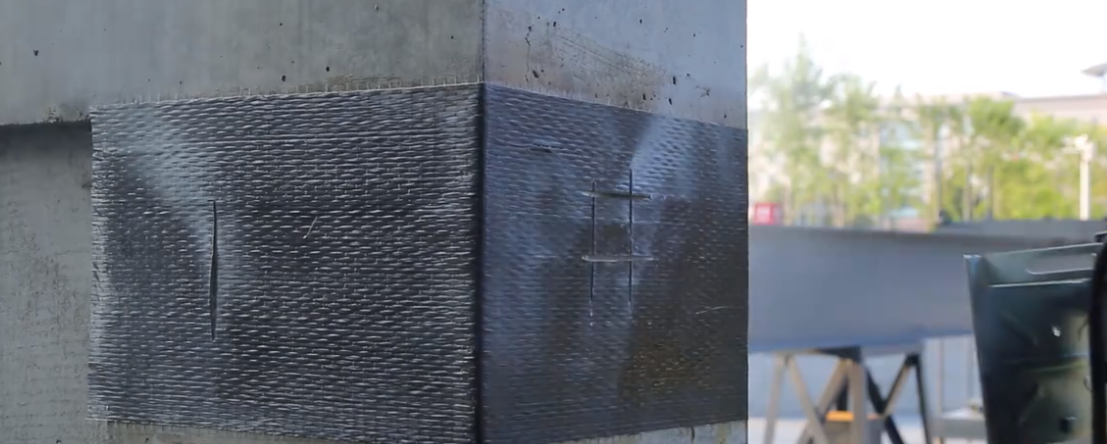

Structural Carbon Fiber Bonding Strength Pull-out Test

1. Substrate surface treatment, cutting and pre-cutting

1) Substrate surface treatment

Clean the surface of the inspection point first and keep it dry

2) Cutting pre-cut seams

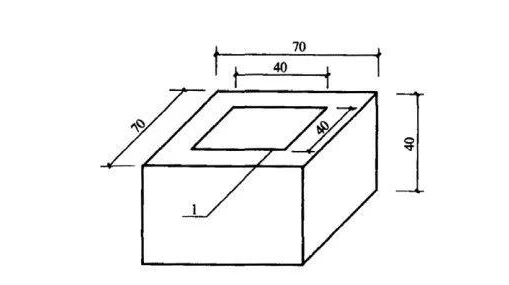

Use chalk to draw a frame of a square test block with a side length of 40mm, and use an engineering hand saw to cut a pre-cut seam with a depth of 10-15mm along the frame line and a seam width of 2mm. The position of the test block should be in the center of the test point. According to the selected cutting machine, the pre-cutting seam can also be cut into a 50mm circle. After cutting the seam, the surface of the test piece should be cleaned.

2. On-site bonding port standard test block and test test block

1)Paste steel standard block

A fast-curing and high-strength adhesive should be used to apply uniformly on the surface of the standard block and the test block. When gluing, there should be no broken seams, and it should be fixed with tape in time, and there should be no disturbance during the 7-day curing process of the adhesive. The positive tension bond strength of the sampled adhesive should be greater than the positive tension bond strength of the structural adhesive that bonds the carbon fiber sheet.

The test block is bonded for the specified time and the test is started.

3. Ready-to-test carbon fiber bonding strength

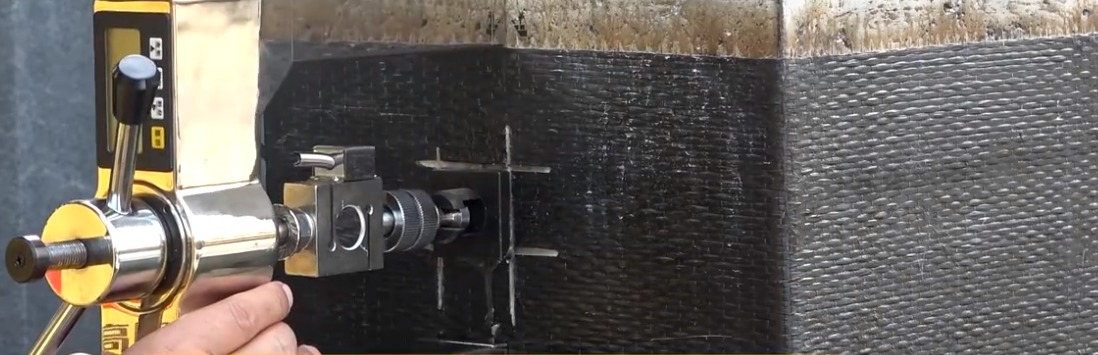

1)Positive pull test

Install the detector. Fix the tension rod on the standard block and rotate the handle to fix the body. Turn on and reset the value to zero. Rotate the handle at a uniform speed of 3mm/min and continue to pressurize. Load at a constant speed of 1500-2000n/min. Reinforce within 1-1.5min until the specimen is damaged. Record the failure load value of the sample and observe the failure mode.

The bond strength of the carbon fiber specimen can be calculated by using the failure load value and the area of the specimen.

F, positive tension bond strength, Mpa

P, the load value when the sample is broken, N

A, the bonding surface area of the steel standard block, mm2

4. Form of destruction

1) Cohesive failure: It should be divided into the cohesive failure of the base material concrete and the cohesive failure of the tested bonding material, as shown in the figure below;

2) Adhesion failure (interlayer failure): it should be divided into the interface failure between the glue layer and the substrate and the interface failure between the glue layer and the fiber composite material or steel plate;

3) Mixed failure: Two or more failure modes appear on the bonding surface.

5. Judgment of the normality of the destruction form shall meet the following requirements:

1) When the failure form is the cohesive failure of the base material concrete, or although there are two or more failure modes, the failure area of the cohesive failure mode of the base material concrete accounts for more than 85% of the bonding surface area. All can be judged as normal damage.

2) When the failure form is adhesion failure, cohesive failure of adhesive layer, or mixed failure where the cohesive failure area of base material concrete is less than 85%, it shall be judged as abnormal failure.

Remark: the tools and pics is from Beijing Haichuang Hi-Tech Technology Co., Ltd. thanks

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

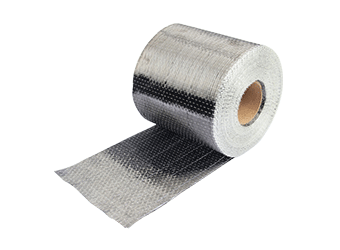

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

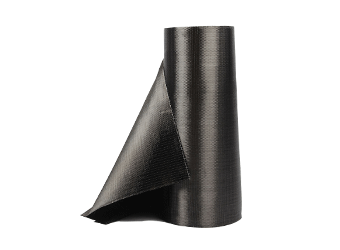

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.