Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Horse FRP DESIGN SOFTWARE - Column Strengthening With CFRP Wrap

Horse Construction Fiber Reinforced Polymer(FRP) Design Software

1.1. Design Criteria

ACI 318M-14 Building Code Requirements for Structural Concrete

ACI-440-2R-17 Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures

1.2. Design Requirement

Required axial load: 10000 kN∙m

1.3.Basic Information

1.3.1 Information of existing member

Height: 610mm

Width: 610mm

Radius of edges of a prismatic cross section confined with CFRP: 25mm

Area of the steel reinforcement: 9650.96 mm2

Concrete compressive strength:45MPa

Yield strength of tensile reinforcement:414 MPa

Elastic modulus of tensile reinforcement: 200000 MPa

1.3.2 Strengthening system

Material: HM-60-I

Ultimate tensile strength of the FRP material as reported by the manufacturer: 4084 MPa

Ultimate rupture strain of FRP reinforcement: 0.0158

Elastic modulus of CFRP: 259251 MPa

Environmental reduction factor: 0.85

Design ultimate tensile strength of FRP: ffu=CE ffu*=3471.4 MPa

Design rupture strain of FRP reinforcement: εfu=CE εfu*=0.0134

Number of layers: 3

2. Design Calculations

2.1 Compute the design FRP material properties

Design ultimate tensile strength of FRP:ffu= CE ffu* = 3471.4 MPa

Design rupture strain of FRP reinforcement:εfu= CE εfu*= 0.0134

2.2 Capacity of existing column ϕPn,existing

Gross area of concrete column: Ag = 372100 mm2

Strength reduction factor: ϕ=0.65

Strength of existing column: ϕPn(A),existing =0.8ϕ[0.85 fc’(Ag - Ast)+ fyAst]= 0.8× 0.65 ×(0.85× 45 ×( 372100- 9650.96)+ 414 ×9650.96)=9286770.95N

2.3 Capacity of strengthen column ϕPn

Effective strain in the CFRP: εfe=κeεfu=0.55εfu=0.55×0.01= 0.0074

Maximum confining pressure due to CFRP jacket: fℓ =2nEftfεfe/D=2×3 × 259251 ×0.333 × 0.0074/862.67 =4.44 MPa

Ratio of Ast to Ag of compression column: ρg = Ast/Ag =9650.96/ 372100= 0.0259

Ae/Ac={1-[(b/h)(h-2rc)2+(h/b)(b-2rc)2]/3/Ag -ρg}/(1-ρg)={1-[(610/ 610)( 610-2×25)2+(610/ 610)( 610-2×25)2]/3/372100- 0.0259}/(1-0.03)= 0.42

Efficiency factor: ka=(Ae/Ac)(b/h)2=0.42 ×( 610/ 610)2= 0.42

Efficiency factor: kb =(Ae/Ac)(h/b)0.5=0.42 ×( 610/ 610)2= 0.42

Additional reduction factor: ψf = 0.95

Compressive strength of confined concrete: fcc′= fc′+ψf3.3kafℓ=45+ 0.95 ×3.3×0.42 ×4.44= 50.88 MPa

Strength reduction factor: ϕ=0.65

Strength of existing column: ϕPn =0.8ϕ[0.85 fcc’(Ag - Ast)+ fyAst]= 0.8×0.65 ×[0.85×50.88 ×( 372100- 9650.96)+ 414 ×9650.96]= 10229409.18 N

3. Conclusion

Original capacity | ϕPn,existing=9286.77 kN

|

Required capacity | Pu,req =10000kN |

Capacity after strengthening | ϕPn,existing=10229.41 kN |

Strengthening system | Material:CFRP HM-60-I Number of layers:3 |

Conclusion | OK |

Notes:

This software application and the results derived from its utilization are intended only for use by professional users with expert knowledge in the area of the intended application. Users must independently verify the results before any use and take into account the site and application conditions, product data sheet and product literature, technical state of the art as well as local applicable standards and regulations.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

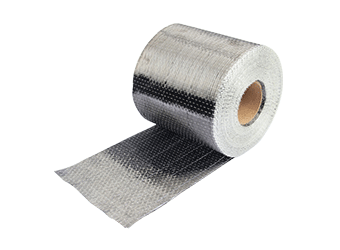

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

Boa impregnação, adesivo de fibra de carbono HM-180C3P para aplicação de fibra de carbono em estruturas para reforço estrutural

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta