Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Why is Epoxy Used in Carbon Fiber Structural Strengthening?

Before answering this question, we must first understand the principle of carbon fiber structure strengthening.

The principle of carbon fiber reinforcement is to prepreg the carbon fiber with high tensile strength into a composite reinforcement material (unidirectional continuous fiber) with epoxy resin. The epoxy resin adhesive is pasted on the structure to be reinforced along the tensile direction or perpendicular to the crack direction to form a new complex, so that the reinforced bonding material and the original reinforced concrete can bear the force together to increase the crack resistance or shear resistance of the structure, and improve the strength, stiffness, crack resistance and elongation of the structure.

So why is epoxy used in carbon fiber structural strengthening?

The main function of epoxy resin is to paste carbon fibers together to fill the gap between carbon fibers, transfer the force between fibers, prevent fiber buckling under pressure, and protect fibers.

An important mechanical property index of epoxy resin is the elongation of the resin. When selecting epoxy resin, the elongation of the resin should be greater than that of the carbon fiber, so as to ensure that the resin will not be damaged before the carbon fiber breaks.

The carbon fiber cloth is not firmly bonded. Possible causes and solutions:

① After the expiration of the applicable period, the viscosity of the impregnant increases, the carbon fiber cloth is not fully impregnated, and the bonding is not firm. The construction must be carried out within the applicable period of the impregnating adhesive.

② The amount of impregnant is too small, the carbon fiber cloth is not fully impregnated, and the concrete is not integrated with the impregnant and the carbon fiber cloth.

③ When the temperature is low, the bubbles in the carbon fiber cloth are not completely discharged during construction. Before construction, component A and component B of the impregnant can be heated separately.

④ The amount of glue used varies with the concrete datum plane. When the amount of glue used on the new base course is too much, it may not bond firmly, while when the amount of glue used on the old base course is too little, it may not bond firmly.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

Boa impregnação, adesivo de fibra de carbono HM-180C3P para aplicação de fibra de carbono em estruturas para reforço estrutural

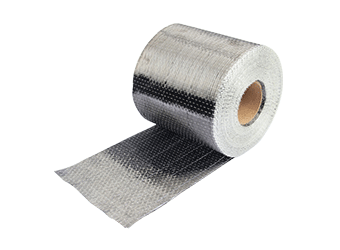

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta