Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

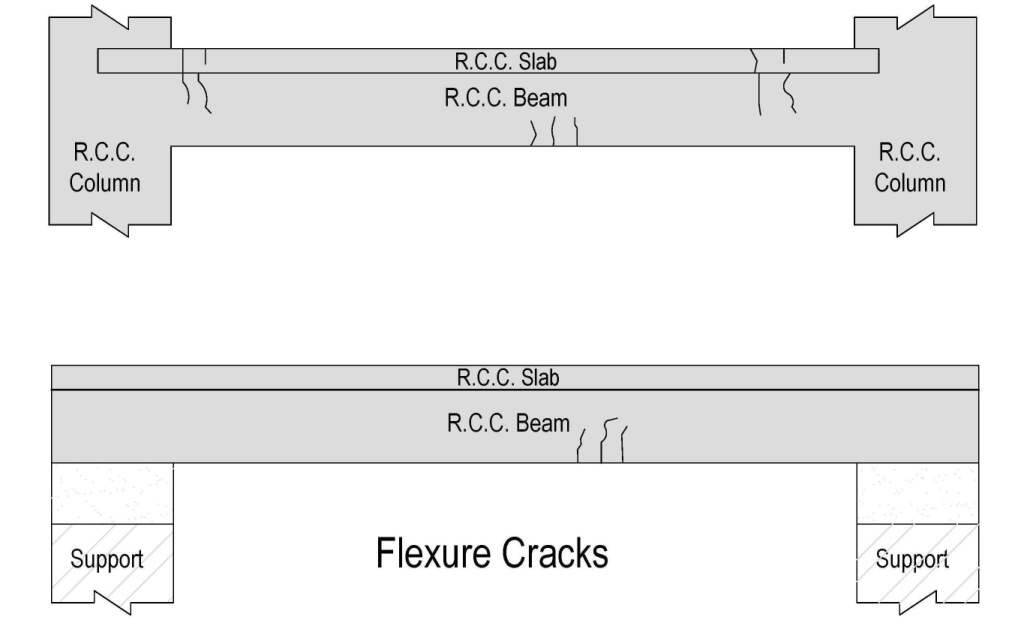

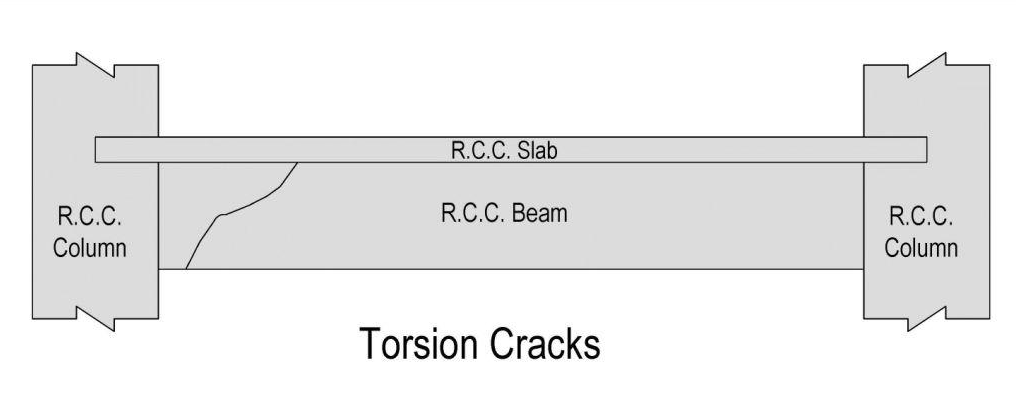

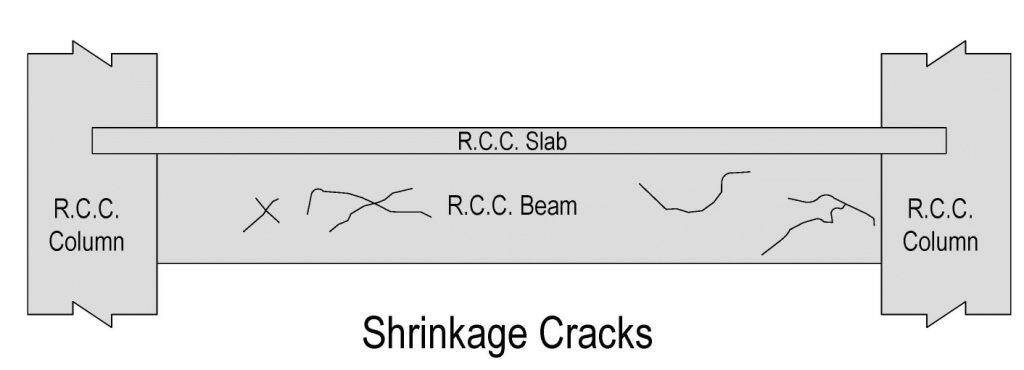

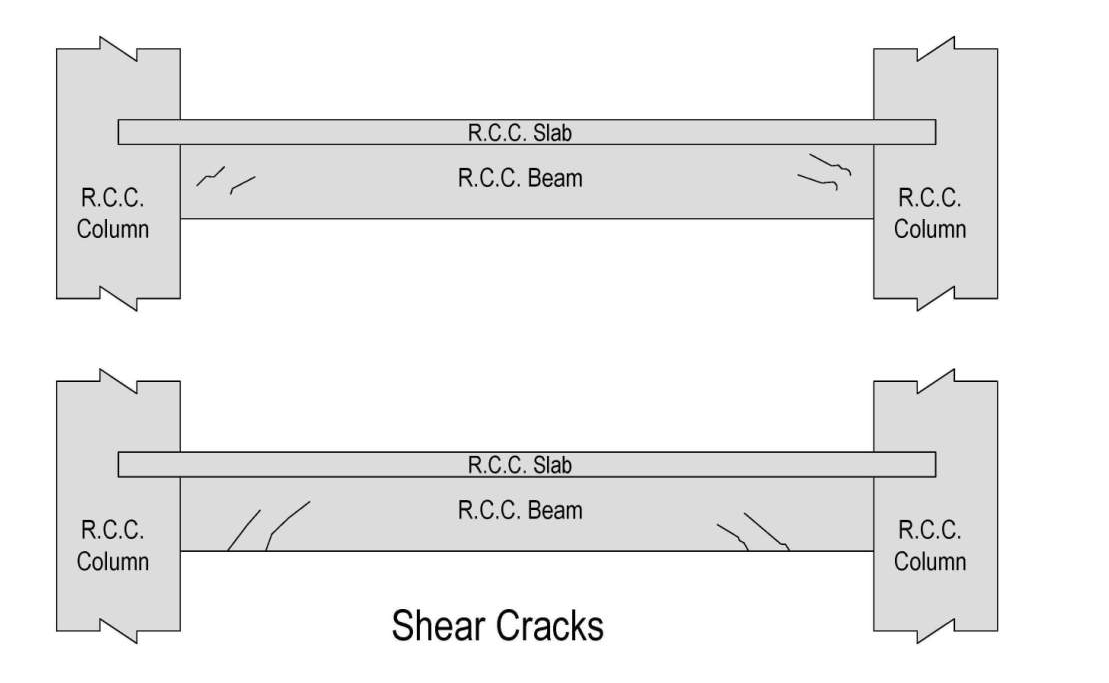

Types & Summary of Cracks in RC Beams

Various types of cracks can occur in RC beams due to flexure, shear, torsion, deflection, and shrinkage. The occurrence of these cracks can be reduced by providing adequate reinforcement, using the appropriate concrete mix, and ensuring proper curing of the concrete. Designing the beam to be stiffer or reducing the loading can also help reduce the occurrence of deflection cracks.

Flexural cracks: Flexural cracks occur in RC beams due to the bending moment applied to the beam. These types of cracks are typically diagonal in nature and occur near the midspan of the beam. The width and depth of the cracks depend on the amount of reinforcement provided in the beam and the magnitude of the bending moment. To reduce the occurrence of flexural cracks, reinforcement should be provided near the bottom of the beam.

Torsional cracks: Torsional cracks occur in RC beams due to the torsional forces applied to the beam. These types of cracks are typically diagonal in nature and occur near the ends of the beam. The width and depth of the cracks depend on the amount of reinforcement provided in the beam and the magnitude of the torsional moment. To reduce the occurrence of torsional cracks, reinforcement should be provided near the ends of the beam.

Shrinkage cracks: Shrinkage cracks occur in RC beams due to the shrinkage of the concrete as it cures and dries. These types of cracks are typically small and occur randomly throughout the beam. The width and depth of the cracks depend on the type of concrete mix used and the amount of water used in the mix. To reduce the occurrence of shrinkage cracks, a low water-cement ratio should be used in the mix, and the concrete should be cured properly.

Shear cracks: Shear cracks occur in RC beams due to the shear forces applied to the beam. These types of cracks are typically vertical in nature and occur near the supports of the beam. The width and depth of the cracks depend on the amount of reinforcement provided in the beam and the magnitude of the shear force. To reduce the occurrence of shear cracks, reinforcement should be provided in the form of stirrups or other lateral reinforcement.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

O adesivo para selagem de rachaduras HM-9 é um adesivo de resina epóxi modificado de dois componentes, frequentemente usado com adesivo para vazamento de rachaduras para selagem de rachaduras e fixação de bicos de injeção.

O adesivo para injeção de rachaduras em concreto Horse HM-120L é um epóxi usado para reparar rachaduras em concreto por injeção. O epóxi tem alta propriedade de penetração. Injeção de baixa pressão de rachaduras em concreto estrutural.

O epóxi de ancoragem injetável Horse HM-500 é um material de ancoragem de alto desempenho, tixotrópico, de dois componentes, à base de resina epóxi para hastes e reforços, adequado para uso em concreto seco e úmido.