Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Key Points of Crack Repair Construction for Rural Highway Bridges

Against the backdrop of rural revitalization, the current situation of rural roads and bridges is receiving increasing attention. With the large-scale construction of "beautiful countryside", rural transportation conditions are becoming more and more convenient. At the same time, there are also many problems with rural roads, such as low overall development level, relatively poor road conditions, inadequate management and maintenance, and significant differences in conditions between different regions. As one of the most basic facilities, the safety of rural roads has also received widespread attention, especially for bridge projects that cross obstacles, whose safety is particularly important. Research has shown that rural road bridges in China have the characteristics of large quantity, low standards, and diverse structural types. Therefore, targeted measures must be taken for design and construction during the maintenance and construction of rural road bridges. At the same time, supervision should be strengthened to detect and solve bridge diseases as soon as possible. Among many types of bridge diseases, structural cracks are one of the most common bridge diseases. If the bridge structure is left unchecked after cracks occur, it will inevitably lead to further deterioration of its damage, ultimately leading to a shortened service life of the bridge, and in severe cases, even leading to bridge collapse, seriously threatening the safety of people's lives and property.

Analysis on the Causes of Cracks in Rural Highway Bridges

Research has shown that the main areas where cracks may occur in rural highway bridges are the web and bottom plates, and the cracks mainly include longitudinal and vertical cracks.

The main reasons for longitudinal cracks are:

a. The overall integrity of the bridge is poor;

b. The pre tensioned precast hollow slab is too thin, resulting in significant local stress on the concrete near the prestressed reinforcement;

c. The chloride ion content in concrete exceeds the standard, leading to corrosion of the steel bars and the formation of bottom plate cracks along the steel bars;

d. Insufficient reinforcement;

e. Poor quality control during construction;

f. Excessive changes in temperature, climate, etc.

The main causes of vertical cracks are:

a. Excessive span of beam and slab;

b. The height of the beam is relatively high;

c. Poor quality control during construction;

d. Long term overload operation.

Both vertical and longitudinal cracks can cause serious harm to bridges.

Bridge crack treatment measures

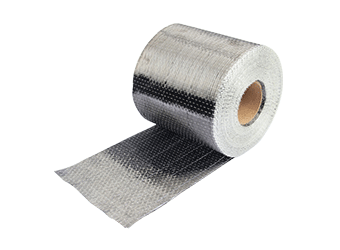

Carbon fiber cloth reinforcement: Carbon fiber cloth reinforcement is suitable for beams with many cracks;

Crack sealing treatment: For cracks with a width ≤ 0.10 mm and no penetration formed;

Pressure grouting method: for cracks with a width greater than 0.1 mm or already penetrated.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O adesivo para selagem de rachaduras HM-9 é um adesivo de resina epóxi modificado de dois componentes, frequentemente usado com adesivo para vazamento de rachaduras para selagem de rachaduras e fixação de bicos de injeção.

O adesivo para injeção de rachaduras em concreto Horse HM-120L é um epóxi usado para reparar rachaduras em concreto por injeção. O epóxi tem alta propriedade de penetração. Injeção de baixa pressão de rachaduras em concreto estrutural.