Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

A Reinforcement Method For Underwater Piles Without Cofferdam: FRP Pile Jakcets

Due to the limited technological level at that time, most bridge piers did not undergo special surface treatment, seawater corrosion, and special electrical corrosion protection for steel bars. Due to the long-term immersion of bridge piers in fresh water or even seawater, especially in the splash zone, various types of bridge piers have suffered varying degrees of corrosion damage and diseases due to the impact of water flow, seawater corrosion, and electrical corrosion of steel bars by seawater, forming a certain degree of safety hazards.

1. Traditional reinforcement methods

In the construction maintenance and reinforcement industry, the protection of underwater engineering structures has always been a thorny issue. After investigation and research, it has been found that structures in the splash zone, such as bridge piers, are particularly severely damaged. For this type of structural repair and reinforcement problem, traditional repair can only use the same materials (concrete, steel, wood) as the original building to complete the repair work, and it requires cofferdam construction, which is very troublesome and time-consuming, and some areas cannot be constructed without cofferdam.

Cofferdam construction: on-site investigation → material preparation → measurement and layout → dredging and excavation of the river channel → soil compaction (throwing and filling stone slag, pouring concrete, driving steel plates, etc.) → forming of the cofferdam.

In addition, due to the use of the same materials without changing their properties, it is impossible to fundamentally improve the corrosion resistance and damage resistance of the structure. Erosion in the splash zone and marine life always exist, requiring regular maintenance within a specified time period. Moreover, each maintenance is time-consuming, difficult to operate, and expensive.

2. Advance underwater FRP pile jackets

The underwater FRP pile jackets reinforcement system belongs to the underwater structure repair and reinforcement system. The principle is to repair damaged structures with epoxy grouting material, cooperate with the fiberglass sleeve to form a unified whole, isolate external erosion, and introduce the "sacrificial anode" technology in the system to protect the steel bars in the concrete from corrosion, thus thoroughly repairing and protecting the damaged structure. Widely used in the reinforcement and repair of structures such as structural foundations, dock foundations, bridge piers and columns, and concrete foundations for public facilities.

advantage

1) High strength, UV resistant, maintenance free.

2) The epoxy grouting material has strong adhesion to the sleeve.

3) Strong applicability, widely applicable to wood, concrete, and steel substrates.

4) Good anti-corrosion performance, resistant to seawater corrosion and various chemical agents.

5) High degree of customization, design and prepare fiberglass sleeves of different sizes and shapes according to actual engineering needs.

6) Resistant to adverse conditions such as dry and wet, cold and hot, freeze-thaw, etc.

7) Good durability, providing both reinforcement and protection for underwater components.

8) Can be constructed underwater without the need for building cofferdams or drainage; Construction is fast and convenient, without the need for bridge sealing or circuit breaking.

9) Can be manually injected or pumped with epoxy grouting material; Complies with marine biosafety standards and can be implemented in both seawater and freshwater.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

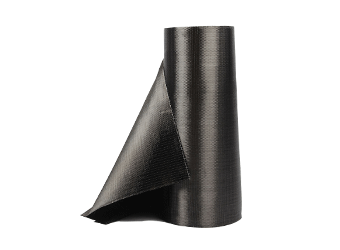

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.

Lâmina de polímero reforçado com fibra de carbono pultrudada (CFRP) de 1,4T projetada para reforço de estruturas de concreto, madeira e alvenaria