Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Construction Process for Underwater FRP Pile Jakcet

The underwater underwater pile jacket reinforcement system is a new repair and reinforcement method. This system eliminates the drawbacks of long construction cycles, high maintenance costs, cofferdam construction, and complex construction techniques. The advantages of simple operation, no cofferdam, low maintenance cost, and good durability. So what is the construction process for underwater pile jacket?

1. Preparation phase

The preparation stage refers to the stage before the simple positioning and installation of underwater pile jacket. After arriving at the site, check the simple dimensions of the underwater pile jacket according to the design drawings, and check whether the raw materials for the simple reinforcement system of the underwater pile jacket are complete. Prepare the necessary tools, especially underwater operation tools, mainly including diving suits, pneumatic equipment, pneumatic drills, etc.

2. Surface cleaning

The cleaning of the surface of the pile column is particularly important, as a clean foundation surface can effectively bond the concrete with the underwater pile jacket to ensure its integrity. For the surface of the water column, clean the floating ash, oil stains, sludge and other impurities on the pier surface with a steel wire brush, or use an angle grinder to chisel the base surface to increase the effective bonding area between the base surface and epoxy grouting material;

For the junction of water surface and air, due to changes in water level, the piers in this area are prone to serious defects such as steel leakage and concrete loosening. Loose concrete should be peeled off first, and steel bars should be rust proofed to prevent further rusting; For underwater construction sites, the surface of the column is covered with a thick layer of mud. A steel wire brush can be used for preliminary cleaning, followed by a pneumatic water gun for cleaning, or the surface of the column can be directly cleaned with a pneumatic water gun.

3. Install the bottom sealing strip

The sealing strip is a hollow foam strip with a diameter of 700-10000mm, and is installed at the bottom of the underwater pile jacket. For the convenience of construction, stainless steel self tapping screws first fix the sealing strip at the bottom of the underwater pile jacket. It should be noted that the length of the sealing strip should be accurately controlled at the simple insertion interface of the underwater pile jacket: if the bottom sealing strip is long, it will affect the docking of the underwater pile jacket to the interface; If the bottom sealing strip is short, it cannot form a sealing ring and may leak during grouting.

Generally speaking, the circumference of underwater pile jacket is relatively large, and the sealing strips will be installed in sections. The joints of the sealing strips should also prevent gaps. For the uneven surface of the sealing strip pile foundation, it should be leveled first to ensure a sealing space is formed with the surface of the concrete foundation. The installation quality of the sealing strip will directly affect the sealing performance of the underwater pile jacket, which is a crucial process After the installation of the sealing strip, it should be inspected. So far, the preparation work has been completed and the subsequent construction process can proceed.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

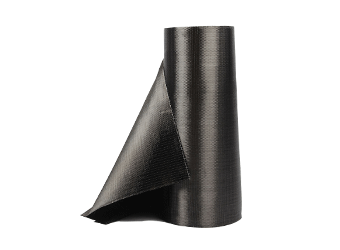

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.

Lâmina de polímero reforçado com fibra de carbono pultrudada (CFRP) de 1,4T projetada para reforço de estruturas de concreto, madeira e alvenaria