Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Beam thickness strengthening method must ensure that the new and old concrete has higher bond strength. The main points are as follows: the base course of the original component joint surface should be solid, the surface is rough and clean, the shrinkage stress of the new cast concrete is small, and the bond performance is good.

In the construction process, beam thickness strengthening method must ensure that the new and old concrete has higher bond strength. The main points are as follows: the base course of the original component joint surface should be solid, the surface is rough and clean, the shrinkage stress of the new cast concrete is small, and the bond performance is good.

1. Processing of the joint surface of the original component

The original structure of the concrete surface should be chiseled in accordance with the specifications required by the reinforcement drawing. The surface of the new and old concrete should be kept on the surface of the tooth, and all the concrete pieces, scum and dust should be cleared, and the water will be washed with water. Before pouring concrete, the original structure concrete interface should be watered 24 hours early to make the interface fully wetted, and the concrete was painted with cement paste, and the concrete was poured before the initial coagulating of the cement.

2.Construction steps of post installed anchor(injectable anchoring adhesive):

2.1.Drill hole to the diameter and depth required. The diameter must be in accordance with anchor size.

2.2.The drill hole must be cleaned with air blower, starting from the bottom of the hole.The drill hole mustbe thoroughly cleaned with steel brush. After brush, to use air blower to clean the drill hole again.

2.3.Inject resin anchor resin into the hole, starting from the bottom, while slowly drawing back the static mixer. In any case avoid entrapping air. For deep holes extension tubing can be used.

2.4.Insert the anchor with a rotary motion into the filled drill hole. Some adhesive must come out of the hole.

2.5.During the resin hardening time the anchor must not be moved or loaded.

3.Connection mode of stirrups with beam thickening and original structure

The hoop reinforcement under the beam is welded to the original beam stirrup by one-sided welding. The length of the weld is 10d, and the spacing between the hoops is the same as that of the original structure.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

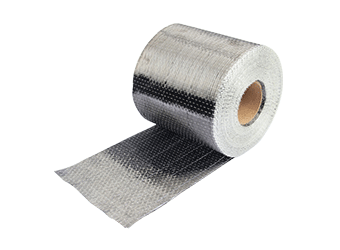

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O epóxi de ancoragem injetável Horse HM-500 é um material de ancoragem de alto desempenho, tixotrópico, de dois componentes, à base de resina epóxi para hastes e reforços, adequado para uso em concreto seco e úmido.