Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Identify the nature of cracks; Ensure structural safety; Ensure durability;Prevent unnecessary damage; Improve the conditions of structural use, eliminate the factors causing cracks; Meet the design requirements and comply with the relevant provisions of the standard specification.

Find out the situation: structure actual condition, the key character of cracks and development situation of cracks.

Identify the nature of cracks: cracks that do not deteriorate in structure, then be treated after being clearly defined.

Clear purpose: seal or reinforcement.

Ensure structural safety: take urgent measures when necessary to prevent vicious collapse accidents.

Meet the use requirements: stiffness, size, space and tightness, leakage prevention, cleanliness, aesthetics.

Ensure durability: prevent steel corrosion and repair material durability.

Determine the appropriate processing time: deal with as stable as possible.

Prevent unnecessary damage: avoid artificial expansion and then repair.

Improve the conditions of structural use, eliminate the factors causing cracks: ensure that cracks do not develop.

The feasibility of the method is reliable, convenient, safe, economical and reasonable.

Meet the design requirements and comply with the relevant provisions of the standard specification.

Compacting leveling method

Application: early shrinkage crack and shrinkage crack before hardening of concrete.

Epoxy adhesive paste

Application: when the concrete is hardened, the width of the surface is <0.3mm, the depth is not large, and the cracks are more numerous.

Treatment points: first clean the surface that needs to be treated, remove oil stains and dirt, and use acetone to scrub, and then brush epoxy mortar repeatedly after drying, once every 3 to 5min, and the thickness of the coating is about 1mm.

Treatment effect: the penetration depth can reach 16 ~ 84mm, which can effectively prevent air and water from penetrating.

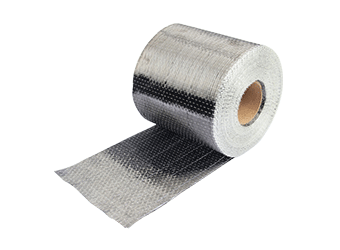

Bonded fiber reinfroced polymer(FRP) compsoite materials

Surface suture

Strengthening and retrofitting measures

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O adesivo para selagem de rachaduras HM-9 é um adesivo de resina epóxi modificado de dois componentes, frequentemente usado com adesivo para vazamento de rachaduras para selagem de rachaduras e fixação de bicos de injeção.

O adesivo para injeção de rachaduras em concreto Horse HM-120L é um epóxi usado para reparar rachaduras em concreto por injeção. O epóxi tem alta propriedade de penetração. Injeção de baixa pressão de rachaduras em concreto estrutural.