Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Before cracks are repaired, we need to measure the cracks first and choose the appropriate method according to the width of the cracks. When the crack width is less than 0.2mm, the crack repair glue is closed. When the crack width is in the 0.2mm~1.5mm, the crack injection adhesive should be injected into the fracture cavity with a certain pressure to strengthen and close the fracture cavity.

Concrete cracks are one of the most common diseases in the building structure. If they do not deal with the cracks which affect the structure safety, it will cause irreversible damage to the building. Then, when the cracks are repaired, what are the construction precautions?

Before cracks are repaired, we need to measure the cracks first and choose the appropriate method according to the width of the cracks. When the crack width is less than 0.2mm, the crack repair glue is closed. When the crack width is in the 0.2mm~1.5mm, the crack injection adhesive should be injected into the fracture cavity with a certain pressure to strengthen and close the fracture cavity. When the crack width is greater than 1.5mm, the pressure grouting method should be adopted.

If there is a slight leakage during construction, temporary plugging measures such as water glass and cement can be adopted, but the quality will be affected. This is not the case in general, but the relevant solutions must be understood.

The grouting pressure should gradually increase. If not gradually increasing, it will cause the following conditions: easy to break the weak point of the closed layer, to re fill the seal or cause the leakage of slurry, and also easily make the slurry flow too fast in the gap to form short circuit, the air can not be discharged and cause the lack of slurry and bubbles.

When the temperature is higher, outdoor construction is best in the morning or evening. If there is a need for construction under high temperature conditions, proper cooling can be carried out. If the cracks are wider, a little talcum powder can be added to the slurry or the amount of diluent in the formula can be reduced. Late inspection is also very important. We need to strictly check every process and record relevant details.

The construction environment should be dry and ventilated. The paste surface should be clean, dry and without oil; the curing temperature should not be less than 5 C, and the curing time can be adjusted according to the specific use.

The construction personnel should take necessary safety precautions, such as wearing masks, gloves, goggles and so on. If the structure glue is not careful to hurt the skin or clothing, it can be immediately cleaned with acetone and rinsed with plenty of water. If you accidentally eat or splash your eyes, you should seek medical attention immediately.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

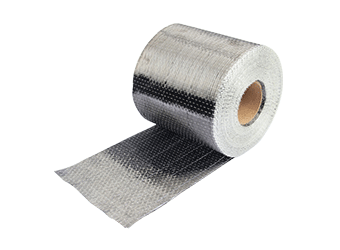

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O adesivo para selagem de rachaduras HM-9 é um adesivo de resina epóxi modificado de dois componentes, frequentemente usado com adesivo para vazamento de rachaduras para selagem de rachaduras e fixação de bicos de injeção.

O adesivo para injeção de rachaduras em concreto Horse HM-120L é um epóxi usado para reparar rachaduras em concreto por injeção. O epóxi tem alta propriedade de penetração. Injeção de baixa pressão de rachaduras em concreto estrutural.