Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

After the steel plate is bonded, a 25 mm thick epoxy mortar protective layer is applied on the surface of the beam. For the slab with a width of more than 0.2 mm and the crack-dense area, the cracks on the top of the slab are chiseled out in Fig. 2, showing C.

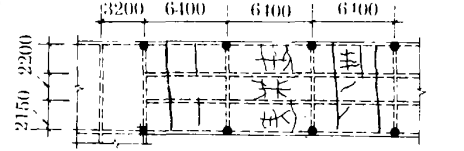

A seven storey building has a basement, with a frame structure and a small foundation. The reinforced concrete side wall beam slab reinforced concrete roof is used in the basement. According to the requirements of urban planning, the first floor of the building is used as a small car parking lot, and the roof of the 3rd beam crack schematic drawing room in the underground is used as a parking lot. The design live load standard value is 4000 cause analysis N/m2. The project was completed and put into operation in August 1995. In November of the same year, a large truck unlawfully drove into the parking lot and moved along an unknown route, resulting in serious cracking of the basement roof due to over-shearing composite action, multiple leakage, affecting the structural reliability and normal use of the basement. Reinforcement and repair measures must be taken.

Serious cracks caused by overloading of beam and slab have shown that local reinforcement yields, which greatly weakens the shear and bending capacity of beam and slab. Parking lot is semi-open environment, such as rain and oil immersion cracks will accelerate steel corrosion, reduce the durability of the structure. Therefore, the beam and slab should be reinforced and closed.

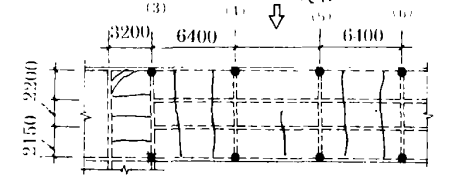

In order to improve the negative bending moment resistance of the secondary beam, 16 mm reinforcing bars are added to the secondary beam.

In the lower part of the beam plate, for the secondary beam, the whitewash layer is cut off, and the vertical shear steel plate is pasted on both sides of the secondary beam within 1800 mm from the support. The steel plate size is 3 x 30 x 400 mm, and the distance is 250 mm material A3 steel, which is the same as the original section stirrups. After the steel plate is bonded, a 25 mm thick epoxy mortar protective layer is applied on the surface of the beam. For the slab with a width of more than 0.2 mm and the crack-dense area, the cracks on the top of the slab are chiseled out in Fig. 2, showing C. Secondary beam cracks are shown in Fig. 3, and the maximum width of the crack is 0.47 mm. No cracks and leakage are found through the eastward joint.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

O adesivo de colagem de placa de aço estrutural HM-120 é um produto epóxi de dois componentes, com forte adesão, cura em temperatura ambiente. Possui excelentes propriedades antienvelhecimento, resistência ao choque em autoadesão e adesão mútua de aço e co

O adesivo para revestimento de placa de aço HM-120M é um adesivo de perfusão estrutural de construção de resina epóxi modificada de novo tipo, especificamente para suportar reforço de barra colada adesiva. Pode ser colado com vários substratos e metais, co

O adesivo para selagem de rachaduras HM-9 é um adesivo de resina epóxi modificado de dois componentes, frequentemente usado com adesivo para vazamento de rachaduras para selagem de rachaduras e fixação de bicos de injeção.