Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

bridge strengthening

A bridge is an important trunk road bridge in Guangxi Province. In 2004, the automobile traffic volume reached 6124 vehicles.

The bridge was built in 1971. The total length of the bridge is 280.60m. The superstructure is a 20-hole 14.00mT simple-supported beam structure. The horizontal beam adopts a five-beam type. The lower structure is a double-column abutment and bored pile foundation. The full width of the bridge is 7m + 2 × 0.75m sidewalk, and the design load is steam -13 and tow -60.

With the increase in vehicle tonnage and years of operation, many diseases have appeared on the old bridge, which needs to be reinforced and repaired. And increase the original bridge's bridge bearing capacity standard to the current standard highway class Ⅱ, making it adapt to the current high-grade highway requirements.

(1) Paste steel plate to enhance shear resistance

On both sides of the inner beam rib of the 1/4 span of the beam end, mainly along the h / 2 range outside the support, Q235 steel plate is glued with epoxy resin and bolted to enhance the shear resistance of the beam body. During construction, the chiseling shall be carried out at the corresponding position of the old beam concrete, and the depth shall not be less than 5mm. The concrete stone was exposed by chiseling and the residue was removed, and the new C30 concrete was poured after wetting the concrete surface. At the damaged part of the beam body, epoxy resin mortar grouting and concrete repairing method are used to repair the beam body.

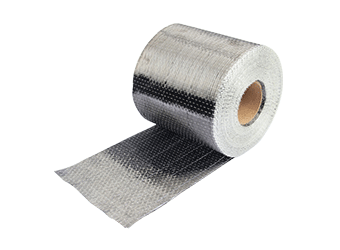

2) Utilize the good tensile properties of carbon fiber plate for structural reinforcement

Two layers of 20cm wide, 450cm and 900cm high-strength carbon fiber plates are used in the bending moment area of the bottom surface of the main beam mid-beam, supplemented by a 12cm U-shaped hoop to strengthen the bending capacity of the beam body. The U-shaped high-strength carbon fiber plate outer hoop with a width of 24cm is used near the fulcrum partition, gradually becoming thinner from near and far, and the beam body is strengthened by shear.

3) Strengthen the horizontal connection between beams

The epoxy resin mortar is used to fill the cracks, and the anchor rod and anchor steel plate are used to reinforce the partition. The thickness of the steel plate is not less than 12mm. At the added middle beam, after drilling holes at the designated position of the beam body, two HRB335 steel bars with a diameter of 28 mm are traversed across the entire bridge and tightened or anchored with steel plates. Then the reinforcement beams and the reinforcement mesh of the partition beam are tied to the reinforcing steel bar to cast the concrete beam.

4) Pavement for thickened bridge deck

Because the original bridge deck pavement is thin, the destruction of the bridge deck pavement directly caused the destruction of the entire wing. At the same time, due to the deflection of the beam body, the repeated action of the vehicle caused the destruction of the beam end. Therefore, the use of thicker bridge deck pavement can protect and strengthen the wing plate, and can effectively increase the effective height of the beam body, increase the pavement participation in the overall superimposed beam effect of the beam body, and effectively improve the bridge bearing capacity .

1. The whole bridge deck is paved with C40 concrete with a thickness of 10cm and reinforced with 15cmX15cmY8 reinforced mesh to increase the joint effect of the beam and the bridge deck. At the same time, in order to strengthen the connection between the beam joints, lay a layer within 1m wide at the joint, and add another layer of steel mesh with the same specifications;

2. Set continuous bridge deck;

3. Replace the support, and replace the original axle roller support with a plate rubber support.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O adesivo para revestimento de placa de aço HM-120M é um adesivo de perfusão estrutural de construção de resina epóxi modificada de novo tipo, especificamente para suportar reforço de barra colada adesiva. Pode ser colado com vários substratos e metais, co

O adesivo para injeção de rachaduras em concreto Horse HM-120L é um epóxi usado para reparar rachaduras em concreto por injeção. O epóxi tem alta propriedade de penetração. Injeção de baixa pressão de rachaduras em concreto estrutural.