Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

marine repair and reinforcemnet

The ocean is a blue country. Vigorously developing marine resources, developing the marine economy, peacefully using and protecting the ocean are important national policies of our country.

Application and corrosion of reinforced concrete in marine environment

The development of marine resources and the construction of marine transportation infrastructure involve a wide range of marine engineering facilities such as ports, oil production platforms, sea-crossing bridges, coastal power plants, and large ships. These facilities are usually composed of steel structures or reinforced concrete structures. Since the ocean is a very harsh corrosive environment, if these major engineering facilities cannot be well controlled, it will cause huge corrosion damage and economic loss.

In order to ensure the durability and safety of various marine projects and maximize the economic and social benefits, anti-corrosion protection work is urgent. Effectively protecting the corrosion of marine engineering facilities can improve the durability and safety of the engineering structure, which is beneficial to environmental protection and resource conservation.

Corrosion damage of reinforced concrete in marine environment

Reinforced concrete structures in the marine environment have long been subjected to single action or combined action of factors such as chloride, freeze-thaw, carbonization, sulfate and alkali aggregate. Not only caused damage to the structural concrete body, but also induced corrosion of the steel bars in the concrete. This results in cracking and spalling of the structural concrete protective layer, a reduction in the cross-sectional area of the reinforcement, a reduction in the bonding force, and a reduction in the bearing capacity. Eventually leads to the destruction of the reinforced concrete structure. Among them, the reinforced concrete located in the spray splash area is most corroded due to the alternating dry and wet seawater, high concentration of corrosive ions, and sufficient oxygen and water supply.

Some of the structure that are build in or close proximity to oceans are

Retaining walls, seawalls

Floating structures

Decks, quays, and piles

Boat ramps, jetties, and bulkheads

Roads, buildings, and aquariums

Repair and reinforcement technology of marine reinforced concrete

Surface coating repair,

Reinforced concrete cathodic protection,

Electrochemical desalination technology,

Concrete alkalizing,

Section repair technology,

Crack repair technology,

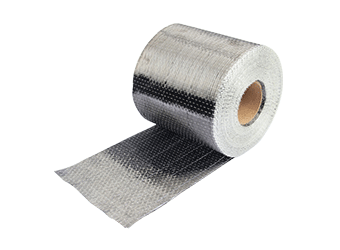

FRP reinforcement technology,

Steel jacketing reinforcement method,

External bonding steel reinforcement method,

Enlarged section method.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O adesivo de colagem de placa de aço estrutural HM-120 é um produto epóxi de dois componentes, com forte adesão, cura em temperatura ambiente. Possui excelentes propriedades antienvelhecimento, resistência ao choque em autoadesão e adesão mútua de aço e co

O epóxi de ancoragem injetável Horse HM-500 é um material de ancoragem de alto desempenho, tixotrópico, de dois componentes, à base de resina epóxi para hastes e reforços, adequado para uso em concreto seco e úmido.