Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

carbon fiber reinforcement

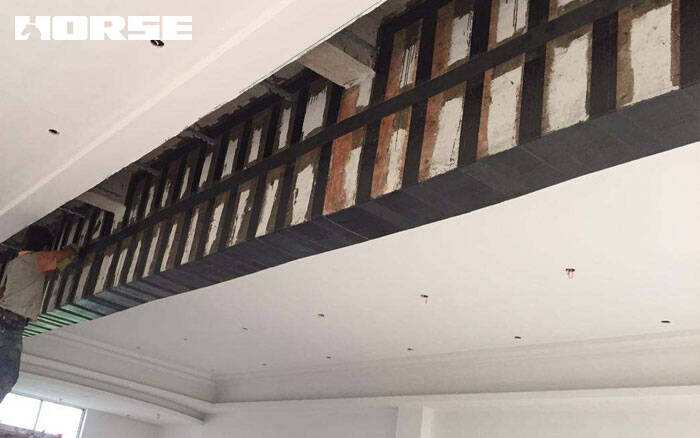

There are many factors that affect the CFRP reinforcement effect and can be divided into two categories.

The first category is the performance and original conditions of the reinforced beam itself: including load conditions, support conditions, beam high-span ratio, shear-span ratio, concrete strength, reinforcement ratio, coupling ratio, CFRP nominal coupling ratio and pasting method Wait.

The second category is the performance of reinforcement materials (including carbon fiber and glue): including CFRP thickness, elastic modulus, anchor length, glue shear strength, thickness, and ultimate elongation.

Among the above influencing factors, the most important factors affecting the shear ultimate bearing capacity and failure characteristics of the beam are the stirrup ratio, the nominal reinforcement ratio of CFRP, the shear span ratio, the way of CFRP pasting, the anchoring performance of CFRP, and the thickness of CFRP (number of layers), shear strength of glue, etc.

1. Influence of beam's hoop ratio on reinforcement effect

The effect of CFRP on the shear reinforcement of beams with a small coupling rate is obvious. When the stirrup rate of the concrete beam is close to the minimum reinforcement rate, the shear resistance of the inclined section of the beam after reinforcement can be increased by 30% to 40%. When the coupling rate is close to the maximum coupling rate, the reinforcement effect is not obvious.

2. Influence of CFRP nominal coupling rate on reinforcement effect

The posted area of carbon fiber fabric has a greater impact on the shear capacity, while the number of layers has a smaller effect. Therefore, the nominal CFRP hoop ratio is generally defined as the ratio of the surface area of the carbon fiber fabric attached to the side of the beam shear zone to the side area of the beam in the shear zone. The nominal coupling rate of CFRP has a greater influence on the reinforcement effect. When the nominal coupling rate is 50%, the load of the inclined section of the beam after reinforcement is only increased by about 20%. When the nominal coupling rate reaches 100%, it can be increased by about 50%.

3. Influence of shear-span ratio on reinforcement effect

When the shear-span ratio is less than 1.5, the bearing capacity of the inclined section of the beam after reinforcement is hardly increased. When the shear span ratio is 2, the ultimate bearing capacity of the inclined section of the reinforced beam can be increased by about 35%. When the shear span ratio is 3, this value can be increased to 40%. Therefore, only for concrete beams with relatively large shear spans are CFRPs suitable for strengthening diagonal sections.

4. Effect of carbon fiber fabric adhesive method and anchor performance on reinforcement effect

Carbon fiber fabric can only exert its high strength characteristics when it is fully anchored. If the upper and lower ends of the carbon fiber fabric are not sufficiently anchored, the first thing to happen is the bond failure between the CFRP and the concrete protective layer, and the strength of the carbon fiber has not yet been fully exerted. Therefore, when strengthening the inclined section of the beam, the appropriate anchoring method should be adopted in combination with the actual situation.

5. Influence of the number of carbon fiber fabric layers on the reinforcement effect

The effect of the number of carbon fiber fabric layers on the increase of the load-bearing capacity of the diagonal section of the beam is not obvious. This is mainly because if a layer of carbon fiber fabric is pasted, the required anchor length is small, and some carbon fiber fabric on the beam side can be pulled off, and the strength is fully exerted. As the number of layers increases, the required anchorage length also increases accordingly. However, the anchorage length that can be provided during shear reinforcement is limited. Therefore, when damaged, the carbon fiber fabric is bonded and destroyed, and its strength is not fully exerted. Of course, in actual projects, if reliable measures can be taken to ensure the anchorage performance of the carbon fiber fabric, then as the number of carbon fiber fabric layers increases, the reinforcement effect should be better. Although the increase in the number of layers does not significantly improve the shear capacity after reinforcement, it has a significant effect on the cracking of the beam.

6. Influence of the condition of the beam before reinforcement on the reinforcement effect

Concrete beams are first loaded until local cracks appear, then unloaded, reinforced, and then reloaded to failure. The results obtained compared with the beams strengthened without prior loading found that the ultimate bearing capacity of the two is almost the same. Therefore, as long as the damage of the concrete beam before loading is not too serious, the condition of the reinforced beam will have little effect on the shear capacity of the beam.

7. The influence of the performance of the glue on the reinforcement effect

Properties such as the shear strength of the glue also have a greater impact on the reinforcement effect. The higher the shear strength of the glue, the more obvious the reinforcement effect. In actual engineering, the construction performance and long-term stability of the adhesive must also be considered when selecting the adhesive.

8. Influence of concrete strength

For the failure mode of cohesive failure due to insufficient anchorage, when the strength of concrete is high, the stress level that the failure surface can bear is high. Corresponding to this, the stress level of CFRP is also higher, and the shear capacity of the beam is also improved.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.