Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

carbon fiber to repair concrete slabs

As a new material, carbon fiber has gradually become a new generation of structural strengthening technology after increasing the cross-section of concrete and sticking steel plate.

So how to use carbon fiber to strengthen the floor slabs? Here, Horse Construction will give you a brief introduction to help you have a preliminary understanding of the construction technology and construction sequence of carbon fiber reinforced floor slabs.

1. Find cracks;

2. Check whether the exposed steel bar is corroded, if there is any corroded, carry out necessary treatment;

3. Remove the original concrete leveling layer along the two sides of the crack, the width is generally 300mm, until the poured concrete surface layer;

4. When cleaning the surface of the concrete, it is necessary to repair the uneven structural layer with leveling glue. After the repaired material is dried, the surface polishing treatment is carried out with a hand-type polisher (diamond sander);

5. Use an appropriate plastic bucket to configure carbon fiber cloth glue on site (mix it evenly according to the proportion of glue), and cut the selected carbon fiber cloth according to the length of construction needs;

6. Apply the primer on the concrete surface, and roll the brush back and forth to ensure that the glue roller brush on the concrete surface is in place and has soaked into each carbon fiber wire;

7. Paste the carbon fiber cloth to the vertical cracks, and compact the carbon fiber cloth with a plastic plate to ensure the effective bonding of the carbon fiber cloth and the concrete without air bubbles. Then brush the carbon fiber cloth glue on the carbon fiber cloth for the second time;

8. When the carbon fiber cloth to be pasted is quick-drying, use coarse sand (river sand at the drying point) to sprinkle on the carbon fiber cloth (to play the role of finding wool, mainly for the next process);

9. At normal temperature, generally do not carry out the next process construction within 3-5 days, and do not encounter obstacles, use something to cover it as far as possible or isolate it with objects around;

10. About 3-5 days after construction (depending on the construction site temperature and curing conditions), the final surface decoration can be carried out.

The carbon fiber reinforced concrete floor slab has the characteristics of space saving, simple construction, light weight, corrosion resistance and good durability, and can greatly increase the service life of the building and reduce the cost of reinforcement. Therefore, it plays an increasingly important role in structural reinforcement projects.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

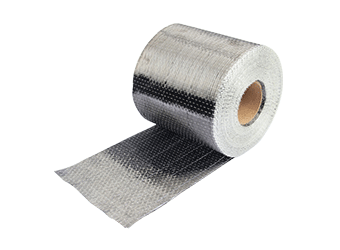

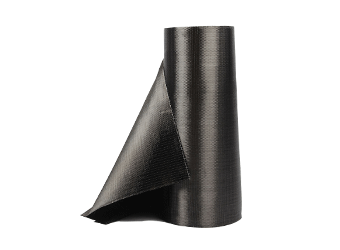

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.