Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

the price of carbon fiber

For the owner, what is the most concerned about the price of carbon fiber for structural reinforcement? Let's discuss this issue below.

Construction steps of carbon fiber reinforcement

The construction steps of carbon fiber reinforcement generally include: concrete surface treatment-primer construction-leveling construction-brushing impregnating glue-cutting carbon cloth-pasting carbon cloth-secondary roller coating impregnating glue-curing curing.

The following is a video of the carbon cloth reinforcement process specially created by Horse, which can be understood at a glance.

From the above steps, it can be seen that the price of carbon fiber reinforcement is mainly affected by two factors: one is the cost of raw materials-carbon fiber cloth and supporting glue, and the other is the labor cost.

01 Raw materials-carbon fiber cloth and supporting glue

There are many carbon fiber cloth brands on the market today, some of which are imported and locally produced. The price ranges from 50 to 300, so owners can make appropriate comparisons when tangling the price of carbon fiber reinforcement.

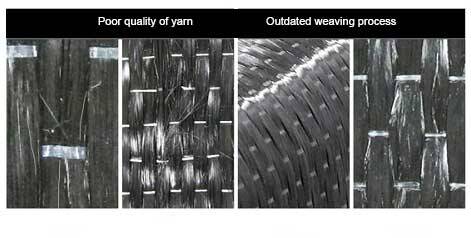

Horse reminds us that the selection of raw materials must be based on quality. In general, the common problems of carbon fiber cloth are wool and joints; wavy and big belly; the strength is not up to standard; the carbon cloth is stiff and easy to fall off; the glue does not match and it is difficult to infiltrate. These problems will lead to insufficient strength of the carbon cloth, which will directly affect the reinforcement effect and cause greater security risks.

In order to provide customers with the best reinforcement materials, Horse uses imported raw materials, aviation-grade 12K small tow fibers, and the monofilament length is 5000 meters without splicing. In addition, Horse adopts a weaving process different from other manufacturers, independently develops creels and bobbins, and adopts an active weft insertion weaving process to reduce damage to carbon filaments. The surface of the carbon cloth produced is smoother, ensuring that the maximum range of strength of each strand is exerted.

In order to provide customers with the best reinforcement materials, Horse uses imported raw materials, aviation-grade 12K small tow fibers, and the monofilament length is 5000 meters without splicing. In addition, Horse adopts a weaving process different from other manufacturers, independently develops creels and bobbins, and adopts an active weft insertion weaving process to reduce damage to carbon filaments. The surface of the carbon cloth produced is smoother, ensuring that the maximum range of strength of each strand is exerted.

At the same time, for the owners who choose materials, they care about the quality and the price of Horse's high-quality carbon cloth. "The same quality compares the price, the same price compares the quality". No matter how it compares, the Hummer brand is the most cost-effective choice. Horse does not sacrifice the quality of products to drive down prices in order to sell.

02 Carbon fiber reinforced construction price

What aspects to consider when choosing a reinforcement company?

1. The company's qualification level;

2. Whether the ranking in the industry is high;

3. Whether the practical experience is rich;

4. The construction fee standard is transparent;

5. Whether the construction technology has modern concept;

6. Whether the certification report can withstand scrutiny.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

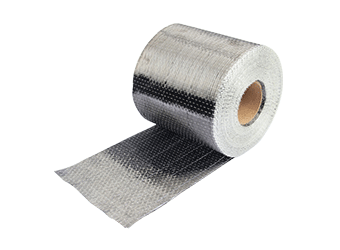

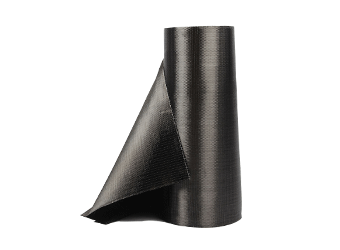

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.