Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

FRP composite reinforcement

FRP materials are man-made high-tech materials, which have excellent mechanical properties and stability. This material is suitable for the maintenance and reinforcement of concrete structures.

At present, there are three kinds of fibers used in reinforcing concrete structures: glass fiber, aramid fiber and carbon fiber.

Advantage of FRP composite reinforcement technology in bridge maintenance

1. Carbon fiber composite materials are usually composed of carbon fiber and other basic materials, with good mechanical properties. The excellent mechanical properties are as follows:

(1) The tensile strength of carbon fiber composite materials is generally above 3500Mpa, which is 7-9 times that of steel;

(2) The specific gravity is small, and its specific gravity is less than a quarter of that of steel;

(3) Has heat resistance, can withstand high temperatures above 2000℃;

(4) The heat capacity is small;

(5) Excellent corrosion resistance and radiation. Using these characteristics of carbon fiber to strengthen the concrete structure can effectively improve the bearing capacity, corrosion resistance, durability and the structure's own weight will not have too much burden.

2. Carbon fiber is a flexible material with a wide range of applications and diverse shapes.

Based on this characteristic of carbon fiber, it can better reflect the advantages of carbon fiber in some special irregular structures. Moreover, the molding of this material is very convenient, and can be applied to any part of various structures and various components, and does not affect the appearance of the structure.

3. The specific gravity of carbon fiber is small, and the light weight determines the use of carbon fiber composite materials for reinforcement. Construction will be more convenient and simple. It requires less space for reinforcement, less impact on the operation of the bridge during construction, higher work efficiency, and cost savings. Take the box girder, which is often used in bridge structures recently, to strengthen bridges even if the internal space is restricted. The specific gravity of carbon fiber is less than a quarter of that of steel. The structure reinforced by this material not only does not increase its own weight, but also has no effect on appearance and size. When carrying out bridge reinforcement, the passage requirements of the reinforced bridge must be considered, and a certain clearance must be ensured. Compared with traditional reinforcement technology, carbon fiber reinforcement technology has more obvious advantages in this regard.

In addition, the following points should be noted of FRP composite reinforcement technology in bridge maintenance

First, the process of strengthening the grassroots level is very important.

The treatment of the base layer directly affects the bonding quality of carbon fiber. Grassroots treatment requires cleanliness, no scum, and smoothness. Before using carbon fiber to reinforce the structure, the surface of the bridge member must be polished, the surface is eroded and the soft concrete is polished off, and after the intact structural layer is exposed, the bridge surface is trimmed and smoothed with carbon fiber material. It should be noted that, where there are bridge cracks, the bridge cracks must be treated. Common treatment methods include grouting and sealing treatment.

The second is to pay attention to the bonding performance when sticking carbon fiber materials, and this is related to the compactness of the rolled material. During the pasting process, repeated rolling must be carried out many times to expel the air bubbles between the materials as much as possible to prevent the air bubbles from affecting the bonding performance.

Third, the quality of bonding is also related to the environment, and environmental factors mainly include temperature and humidity. Too low or too high temperature, too high humidity, etc. will affect the bonding quality of the material. The relevant regulations stipulate that when the temperature is less than 5 ℃, the curing and strength of the impregnated resin will be greatly affected, so the construction must be stopped immediately. And when the temperature is greater than 60 ℃, you must take the relevant thermal insulation protection measures.

Due to the influence of long-term planning, construction and other factors in the bridge design process, many existing bridges in China can no longer meet the requirements of use and need to be strengthened. The introduction and application of new carbon fiber materials in bridge reinforcement in China is not long, but its excellent performance has been fully reflected in the bridge structure reinforcement project. This technology will be applied in more and more reinforcement projects.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

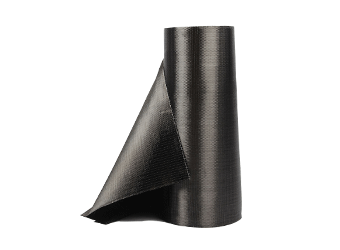

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

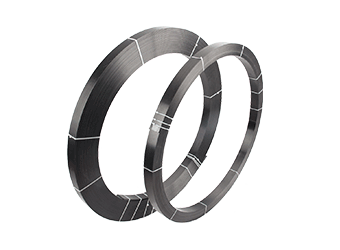

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

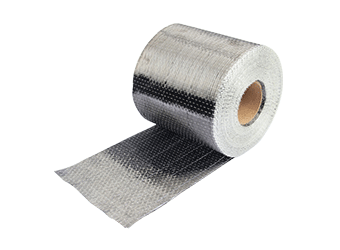

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.