Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Carbon fiber reinforced polymer

In actual engineering construction, due to construction quality problems or design changes after the completion of the construction, the building structure often needs to be reinforced, modified and maintained. Among them, the reinforcement technology of carbon fiber reinforced polymer to strengthen the concrete beam has unique advantages. For example, it has good reinforcement effect, strong corrosion resistance, easy construction, and space saving. This article will combine an engineering example of a hotel with a frame structure to discuss the strengthening effect of carbon fiber cloth reinforcement technology on concrete beams.

Project Overview

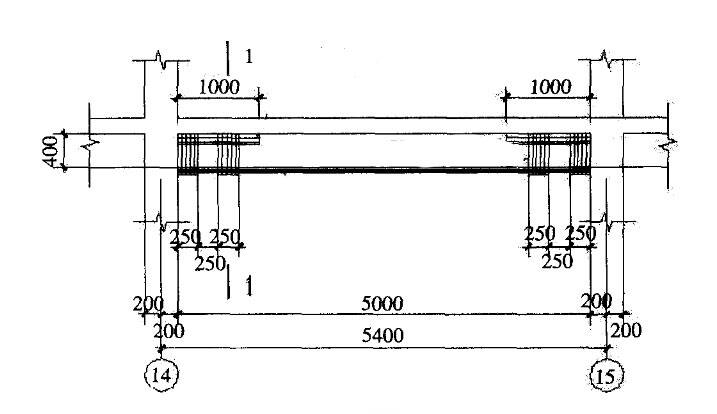

The building was originally designed as an eight-story cast-in-place concrete frame structure, and the concrete strength grade is C25. The cross-section size of the frame column is 400mmx650mm, 350mmx500mm. The size of one to three-story frame beams is mostly 250x550mm and 400x650mm, the size of six to eight-story frame beams are 250x400mm and 400x 40mm, and the secondary beam size is mostly 250x400mm. After inspection and appraisal by the relevant inspection company, the bearing capacity of the six frame columns within the B-E axis and 14-15 axis range from the first floor to the third floor is insufficient, and the frame beams are insufficient (Mainly frame beams in the B-C axis and 14-15 axis range from the second to eighth floors). The rest of the concrete components of the building meet the requirements for use after transformation.

Reinforcement design

Carbon fiber cloth is now used to strengthen the beams (mainly the frame beams in the range of the B-C axis and the 14-15 axis of the second to eight layers). Two layers of carbon fiber with a width of 250mm and a thickness of 0.111mm are pasted on the bottom of the beam, and six U-shaped hoops with a width of 100mm are pasted on both ends of the beam. The clear distance is 50mm as shown in Figure 1.

Construction technology

Since the building was built in the mid-1970s, some components have been cracked and damaged. For the treatment of the adhesive interface, it is first necessary to remove the degraded concrete that has fallen off and corroded the surface of the component, and repair the exposed concrete structure layer with materials. Then some cracks are sealed to remove surface oil, laitance and other impurities until the new surface of the concrete structure is completely exposed. The corner sticking part of the component should be polished into a circular arc shape with a radius of at least 20mm. In actual construction, the impregnating resin should be prepared according to the process regulations provided by the product manufacturer. The bottom resin is evenly smeared on the concrete surface. When the carbon fiber cloth is pasted, the carbon fiber cloth is gently pressed on the position to be pasted by hand. A special roller is used to repeatedly roll along the fiber direction to squeeze out the bubbles, so that the impregnated resin can fully penetrate the carbon fiber cloth. Then sprinkle the coarse sand on the surface of the carbon fiber cloth so that the coarse sand can be effectively pasted on the outer fiber cloth. It should be noted that the lap length of the carbon fiber cloth along the force direction is not less than 100mm. When using multi-layer carbon fiber cloth to reinforce, the overlap position of each layer of carbon fiber cloth should be staggered. The staggering distance is not less than 250mm and not less than 1.5 times the overlap length U. When attaching the first layer of carbon fiber cloth to the bottom of the beam, divide it into two pieces, which can increase the bearing capacity. The carbon fiber cloth at both ends of the beam needs to be hooped with U-shaped hoops to prevent peeling damage.

In conclusion

Reinforcing concrete beams with carbon fiber reinforced polymer reinforcement technology can greatly improve the bearing capacity of the construction, and the reinforcement effect is significant. At the same time, this method is simple to construct, does not occupy space, and has a wide range of application prospects. In this project, the reinforced beams have passed the appraisal and have met the requirements of bearing capacity.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

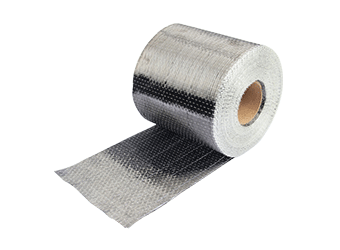

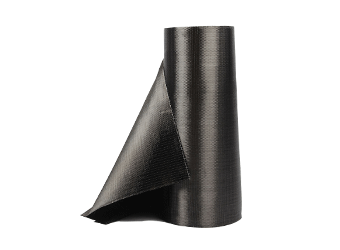

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.