Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

carbon fiber sheet, crack injection

Project Overview

Fuli Oriental Section I (Building 1-6, Building 10, basement) is located in Groups 2, 3, 4, 12, 13, and 14 of Shengli Village, Baohe Township, Chenghua District, Chengdu City, Sichuan Province. The terrain of the site is relatively flat and the transportation is convenient. The nature of the project is a high-rise residential building. The elevation is equivalent to the absolute elevation of 525.60 m, with a construction area of 188,000 square meters. Building No. 1 is composed of two units, both of which are 18 floors above ground and 1 floor underground. The total height of the building is 55.45 m. It adopts a cast-in-place reinforced concrete short-leg shear wall structure, and the foundation adopts a monolithic raft foundation. The structural design is fortified according to degree 7, the design basic earthquake acceleration value is 0.10g, and the earthquake resistance level of the shear wall is level 3.

On-site construction progress

When the earthquake occurred, the main structure of Building No. 1 had been topped off and entered the interior decoration stage

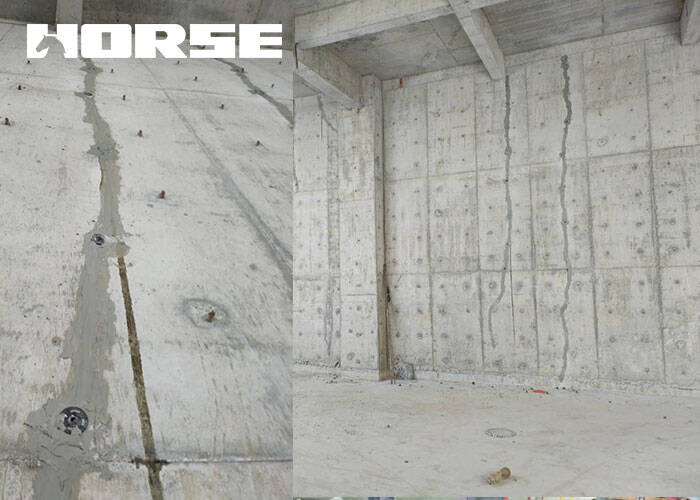

On-site inspection

After the "5•12" magnitude 8.0 earthquake in Wenchuan, Sichuan, the construction unit commissioned the Tongji University Housing Quality Inspection Station to conduct post-earthquake housing structure safety inspections on the Fuli Dongfang Project.

1) Test of concrete strength

When the earthquake occurred, the main structure had already been completed and the concrete had finished final setting, so the concrete strength of Building 1 was not tested on site.

2) Inspection of structural components

Horizontal cracks appeared on the surfaces of the 2-Q-2-M and 1-Q-1-M shear walls on the 13th floor of Building 1.

3) The cracks in the shear wall are caused by resisting the horizontal shear force caused by the earthquake, which is mainly related to the shear span ratio of the shear wall. The local component cracking and minor damage caused by the earthquake have little impact on the structural safety of Building 1. However, in order to ensure the smooth completion and safe use of Building No. 1, Tongji University's Housing Quality Inspection Station requires that a qualified construction unit be entrusted to treat and construct cracks with epoxy resin sealing and carbon fiber cloth reinforcement.

The proposed treatment method

The cracks of the 2-Q-2-M and 1-Q-1-M shear walls on the 13th floor of Building No. 1 were filled with epoxy resin, and a layer of carbon fiber cloth was pasted on the surface after sealing.

Process flow

1) Crack grouting

Crack treatment: bury the grouting nozzle, seal the joint, check the seal, configure the grout, finish the grouting, and check.

2) Reinforcement treatment with carbon fiber cloth

Concrete surface treatment, make up and level, configure and paint the bottom impregnation resin, paste carbon fiber, paint the surface impregnation resin, and check the quality.

Test results

The Chengdu Construction Engineering Quality Inspection and Testing Station conducted an on-site sampling test of the positive tension bond strength between carbon fiber cloth and concrete. The test results showed that the construction quality of the crack treatment of the shear wall of Fuli Dongfang No. 1 building was qualified.

Concluding remarks

1) Seal the cracks of the two shear walls 2-Q-2-M and 1-Q-1-M on the 13th floor of Fuli Dongfang No. 1 building by pouring epoxy resin and using pasted carbon fiber cloth for reinforcement. So as to ensure that the safety performance of the structure meets the design requirements;

2) Thousands of pairs ensured timely and effective treatment of the cracks, ensuring that the project was successfully completed on August 28, 2009 and delivered on schedule;

3) At the same time, customers' concerns about the quality of houses after the earthquake have been eliminated to a large extent, customer satisfaction has been improved, and the company has won good social benefits.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta

Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e fortalecer elementos estruturais de concreto.