Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Prestressed Carbon Fiber Laminate Reinforcement System

Since the successful development of the Horse prestressed carbon fiber composite laminate reinforcement system in 2012, it has been successfully used in a number of practical engineering reinforcement examples, and has achieved good reinforcement effects and long-term stability.

In the process of continuous application, the Horse prestressed carbon fiber laminate reinforcement system relies on theoretical analysis and experimental verification to improve the stability and anchoring efficiency in various aspects such as materials, parameters, and molding processes. So far, 3 generations of improved versions have been completed, and new anchors and fixtures that are more efficient and economical are still being verified.

Horse's prestressed carbon fiber composite laminate reinforcement system adopts a wedge-shaped self-locking anchorage form, which makes the anchorage system in a state where the greater the tension and the corresponding clamping force, the relative displacement between the clip and the carbon fiber laminate is avoided. And thereby clamp the carbon fiber laminate to overcome the tensile force.

At the same time, because the taper of the clamp is controlled at a reasonable value, the clamp will not cause too much stress during the process of clamping the carbon fiber laminate, so as to damage the carbon fiber laminate. The clamp adopts the form of a corrugated toothed anchor, which increases the friction coefficient between the clamp and the carbon fiber laminate, so that the clamp can clamp the carbon fiber laminate under a small pressure condition, and avoids the crushing of the carbon fiber laminate due to excessive pressure.

In the process of continuous application improvement, Horse's prestressed carbon fiber composite panel system has developed the following advantages:

1) Anchor channel and clip adopt reasonable inclination angle, tooth pattern angle, tooth pattern depth and tooth pattern to extend the length of the clip. It makes the contact between the clip and the carbon fiber laminate closer and firmer, and overcomes the common problems of sliding and splitting of the carbon fiber laminate during the tensioning process.

2) The anchor frame adopts a one-piece stamping forming process, which has high overall strength and avoids insufficient strength caused by welding and uneven stress distribution in the welding seam.

3) The anchor block channel and clip adopt high-precision wire cutting technology, and the error is controlled within 0.1mm. The actual force condition and the theoretical analysis have a high degree of fit to ensure the tensioning effect.

4) The clip and the anchor block are integrally cut and formed, and the anchor block and the clip number correspond to each other to achieve an excellent fit and adaptability of the contact surface between the anchor block and the clip, and ensure uniform force.

5) The split design is adopted, and the parts are packaged and transported separately, which is easy to replace.

6) Use fixed anchor bolts to fix the anchor block and the anchor frame to overcome the influence of the bending moment caused by the eccentric tension on the overall system.

7) Only slot the anchor block, the slot depth and slot area are small, and the damage to the original component is reduced.

8) Using the on-site installation form, the cutting length of the carbon fiber laminate can be flexibly adjusted according to the on-site situation, avoiding the disadvantage that the integrated anchor cannot change the length of the carbon fiber laminate.

9) The installation parts are simple, except for the anchor frame, anchor block and clip, the rest are standard parts; meanwhile, various tooling required for installation are provided to simplify the construction process.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

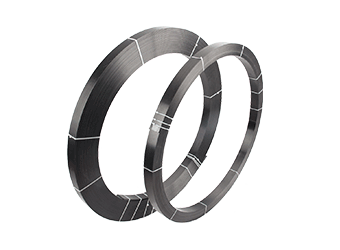

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.

O adesivo laminado de fibra de carbono Horse HM-120CP é um adesivo de base epóxi de componente duplo com forte resistência de ligação, resistência ao cisalhamento e resistência antienvelhecimento. É um epóxi usado para unir laminados de fibra de carbono pa