Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Applications of Fiber Reinforced Polymer(FRP) in Structure Retrofitting

1.1 Flexural strengthening performance

Pasting FRP in the tension zone of the concrete structure can effectively improve its bearing capacity and inhibit the propagation of cracks. The failure characteristics of the concrete structure after FRP addition are quite different from the ordinary concrete structure and the concrete structure reinforced with steel, and the calculation method of its bearing capacity is also different.

1.2 Shear reinforcement performance

Pasting FRP on the side of the shear area of a concrete beam can effectively improve its shear resistance. The commonly used shear reinforcement methods in engineering include side pasting, U-shaped pasting and wrapping pasting. Among them, wrapping pasting has the best effect. The main parameters that affect the shear resistance of FRP include the stirrup ratio of the beam, the concrete strength, the FRP reinforcement ratio, the shear span ratio of the beam, the bonding method and anchoring performance of FRP, the material properties of FRP and the adhesive itself, etc.

1.3 Seismic reinforcement performance

By outsourcing FRP to constrain the concrete in the plastic hinge area to increase the ultimate compressive strain of the concrete, the ductility of the members can be improved, which is beneficial to the seismic reinforcement of the structure.

1.4 Anti-fatigue reinforcement performance

The fatigue of FRP sheet reinforced components is divided into bending fatigue and shear fatigue. According to the load form, it can be divided into fatigue problems under constant amplitude load and variable amplitude load. The fatigue strength of the FRP sheet reinforced component is not only related to the fatigue resistance of the original concrete structure, but also related to the fatigue fracture ability of the FRP plus the same part and the fatigue resistance of the FRP sheet and the concrete interface. Concrete flexural fatigue theory can be used to evaluate the fatigue resistance of the original concrete structure.

1.5 Prestress technology

For flexural members with excessive deflection or severely cracked concrete beams and slabs, simple FRP patch reinforcement methods are difficult to effectively enhance their rigidity, and the role of materials cannot be fully utilized. The use of prestressed FRP reinforcement technology can balance part of the load of the reinforced beam, effectively reduce the deflection deformation of the reinforced beam, delay the cracking of the beam, reduce the width of the crack, reduce the possibility of early peeling failure, and improve the bearing capacity of the beam.

1.6 Durability reinforcement performance

1.7 Strengthening performance of masonry structure

The failure form of the wall has changed from brittle shear failure before the addition to ductile bending failure after reinforcement, which greatly improves the deformability, strength and ductility of the wall. It can effectively reduce the shear deformation, improve the overall ductility and seismic performance of the structure, and increase the bearing capacity of the masonry structure. FRP reinforcement can significantly increase the in-plane horizontal shear strength of the wall, enhance the deformation capacity, and improve the ductility of the structure.

1.8 Strengthening performance of steel structure

In addition to the use of FRP for anti-corrosion, anti-aging and other general reinforcement of steel structures, the innovation of reinforcement methods for steel structure buildings and steel products has also become an issue of concern to people.

1.9 Other reinforcement performance

Due to its many advantages, FRP has broad application prospects in structural anti-explosion

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

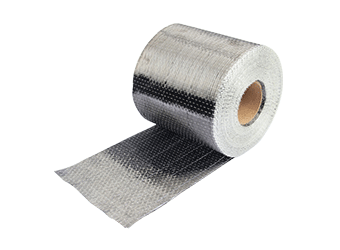

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

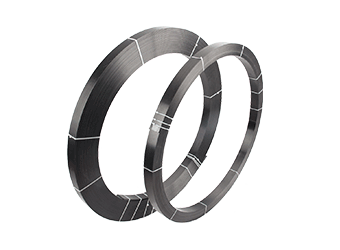

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.