Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

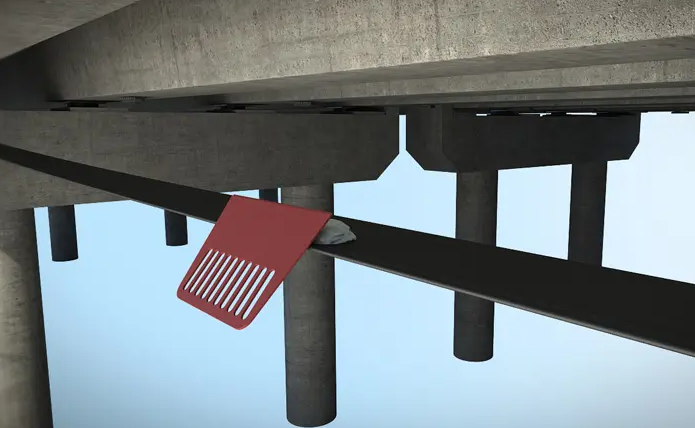

Reinforcing The Wharf With Prestressed Carbon Fiber Material

Under the influence of marine environment, material deterioration, construction defects, service life and other factors, port engineering will be damaged and destroyed to varying degrees, and even local collapse accidents will occur.

According to the inspection reports over the years, most of the pier longitudinal beams, plates, pile foundations, etc. have various degrees of disease. At present, due to the obvious drawbacks of the traditional dock reinforcement technology, a new type of cost-effective technology is urgently needed.

Carbon Fiber Reinforced Rolymer (CFRP) has the characteristics of high strength, light weight, simple construction, fatigue resistance and corrosion resistance, and has good application prospects for the reinforcement of wharf structural engineering.

Reinforced with carbon fiber cloth, it has a certain effect on improving the flexural bearing capacity of the beam plate, which can increase the bearing capacity by about 10% to 20%. However, carbon fiber cloth is passive reinforcement, the material utilization rate is low, and the material can only exert about 10% of its strength under the limit state.

The external prestressing reinforcement technology of carbon fiber plate is adopted to actively improve the bearing capacity of the beam plate, and at the same time, it also solves the unfavorable factors such as peeling of carbon fiber cloth.

Compared with the traditional reinforcement technology, the prestressed carbon fiber plate bridge reinforcement technology has the advantages of not increasing the structure weight, greatly improving the bearing capacity, increasing the rigidity, convenient construction, short construction period, and no maintenance in the later period.

The prestressed carbon fiber plate anchor system overcomes the above defects by applying prestress to the carbon fiber reinforced composite material. After prestressing the carbon fiber, the strain hysteresis of the carbon fiber sheet is avoided. Effectively exert the strength of the carbon fiber plate and improve the bearing capacity of the structure. At the same time, the flexural rigidity of the flexural member is improved, the deflection of the original member is reduced, and the deformation and crack propagation of the member are restrained. The contradiction between the ratio of carbon fiber strength and elastic modulus is solved, and the utilization of carbon fiber strength far exceeds the situation without prestressing.

Prestressed carbon fiber plates utilize carbon fiber strength far beyond what would otherwise be the case without prestressing. And corrosion resistance, but also solve the shortcomings of conventional carbon fiber cloth, such as poor durability and easy peeling. It has very good economic and social benefits, and also has certain guiding significance for the reconstruction of the old wharf in the future.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.

O adesivo laminado de fibra de carbono Horse HM-120CP é um adesivo de base epóxi de componente duplo com forte resistência de ligação, resistência ao cisalhamento e resistência antienvelhecimento. É um epóxi usado para unir laminados de fibra de carbono pa