Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Prestressing CFRP strip can greatly improve the strength and stiffness of the reinforced concrete members, and reduce the deflection and deformation of the structure more effectively, and can reduce and seal the cracks

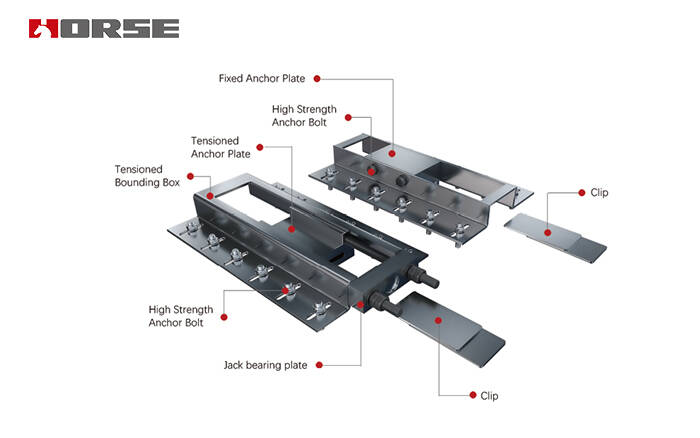

1) the prestressed carbon fiber reinforced system adopts its own unique design of anchorage method. After many studies and tests, the anchorage efficiency coefficient is more than 0.95, it can give full play to the high strength of carbon fiber board, and greatly improve the use rate of carbon fiber material.

2) prestressing CFRP strip can greatly improve the strength and stiffness of the reinforced concrete members, and reduce the deflection and deformation of the structure more effectively, and can reduce and seal the cracks.

3) the CFRP strip's structure size is small, the material is light and thin, basically does not increase the original structure weight, does not affect the original structure use space, after reinforcement does not leave traces.

4) construction and installation is convenient, there is no wet operation, no large construction machinery is needed, and construction occupies less space.

5) CFRP strip has good durability and corrosion resistance.

6) reduce dependence on adhesives and construction in winter.

Pre-stressed CFRP Strips technical indicators:

1) static load anchoring performance: anchorage efficiency coefficient is less than 95%, the total strain is more than 1.2%;

2) fatigue performance: by taking 65% of the standard value of the tensile strength of the carbon fiber plate as the upper limit of stress, the stress amplitude is 100Mpa, and the cycle load times of the fatigue test are 2 million times.

3) relaxation performance: it is verified by the relaxation test of 1000h.

Pre-stressed CFRP Strips technical advantages:

1) mainly depends on mechanical anchorage, and does not depend on adhesives. It is outstanding in reliability, safety and durability.

2) high strength of carbon fiber strip

3) the utilization rate of materials is high. The highest tensile stress is 0.65 σb.

4) the construction is fast and convenient, the anchorage and the carbon board assembly are made in the factory. The jacks can be removed after the field installation is finished, and the requirements of the site construction site, auxiliary measures and climate conditions can be reduced to the maximum.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.