Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Case Study On How Prestressed Carbon Fiber Plate Reinforce Concrete Double T Slabs

Engineering background

The concrete double T slabs of a factory that had excessive deflection. The factory building is a single-story frame structure, the beams and columns are cast-in-place frame members, and the slabs are prefabricated prestressed concrete double T slabs. Slab size: 29980mm*2390mm. T-beam bottom width is 110mm, web height: 710-1085mm.

Analysis of current situation and causes of double T slab diseases

On-site diseases:

① There are many cracks on the T beam of the double T slab (the crack spacing within 10 meters of the mid-span is 1m, and the crack spacing within 10 meters of the beam end is 1.5m). The cracks penetrate the bottom slab and extend 30-35cm toward the web. The crack width is 1-2mm wide.

② The double T-slab sinks as a whole, the mid-span deflection of the cracked T-beam is about 30cm, and the mid-span deflection of the uncracked T-beam is about 25cm. (Note: The blue line in Figure 5 is the level stretched from the bottom of the beam at both ends, and the deflection is clearly visible)

Disease cause analysis:

① The actual load of the double T slab is much greater than the design load (the design load is 150kg/m2, the actual load is about 400kg/m2)

② The prestressed steel strand may have excessive prestress loss.

③ The strength of concrete is insufficient. (Concrete that is not dense and pitted is more common)

Reinforcement plan and construction technology

Maintenance and reinforcement plan:

As a prestressed concrete structure, this prefabricated double T slab has many transverse cracks, with a maximum crack width of 2mm and a maximum deflection of 30cm. According to the shape, distribution and development of cracks, the double T slab shows insufficient bearing capacity. In order to improve the durability and safety performance of the double T-slab, the 30m-span T-beam is reinforced with prestressed carbon fiber plates.

① For the 110mm wide T-beam, use a 50mm wide and 3mm thick carbon plate.

② Based on the span of 30m and the distribution of cracks, a 25m-long carbon plate is used.

③ In view of the on-site disease, the tension value of the prestressed carbon plate is designed to be 1000MPa (15t).

Construction technology:

① Set up a steel pipe frame under the double T-slab T beam.

② Drill holes at the anchorage position of the prestressed carbon plate.

③ Installation of prestressed carbon plate anchors.

④ Installation of prestressed carbon fiber plate.

⑤ Prepare glue and apply structural glue.

⑥ Prestressed tensioning.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

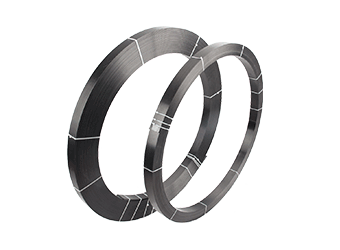

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.

O adesivo laminado de fibra de carbono Horse HM-120CP é um adesivo de base epóxi de componente duplo com forte resistência de ligação, resistência ao cisalhamento e resistência antienvelhecimento. É um epóxi usado para unir laminados de fibra de carbono pa