Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

When the bonding quality is not required, the carbon fiber fabric should be cut off along the edge of the empty drum. The size of 100mm is extended to the outer edge of the same carbon fiber material, and the same binder is used in the original.

Self inspection and acceptance criteria for CFRP strengthening are listed in the table below

| Item | Standard of qualification | Test method | Region |

| Stickup position of carbon fiber fabric | Compared with the design requirements, the centerline deviation is less than 10mm | Steel scale measurement | Total |

| Amount of carbon fiber fabric | More than design quantity | Calculate according to the measurement | Total |

Paste qualit | 1. single empty drum area < 1000mm2, filling glue repair; above 1000mm2, mending. 2. the ratio of hollowing area to total paste is less than 5%. | Hammer | Total |

Carbon fiber adhesive thickness | Carbonf fiber laminate: 2mm + 1.0mm | Steel scale measurement | Sampling inspection |

| Carbon fiber fabric: <2mm |

When the bonding quality is not required, the carbon fiber fabric should be cut off along the edge of the empty drum. The size of 100mm is extended to the outer edge of the same carbon fiber material, and the same binder is used in the original.

When the strength fails to meet the requirements, the carbon fiber composite material represented by the sample inspection shall be stripped and redone.

The self inspection method of CFRP strengthening is visual inspection or percussion. Inspection standard: the surface of the reinforcement should be strengthened without any glue, gaps, dry yarn, wrinkles, bubbles and sunken defects. Detection time: 3-5 days after completion, check the area with visual or metal mallet (small).

Defect handling of self inspection

Shortcoming | Treatment measures |

Lack of glue and ga | Applying more adhesive |

Crumpled (carbon fiber) | Grinding and adding subsidized carbon fiber |

Dry yarn | Dismantle and adding subsidized carbon fiber |

Sunken | Applying more adhesive |

Bubble | Length is more than 3mm, grinding and adding subsidized carbon fiber |

| Length is less than 3mm, dismantle and adding subsidized carbon fiber | |

| Iintensive style, grinding and adding subsidized carbon fiber | |

| Centralized, applying more adhesive |

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

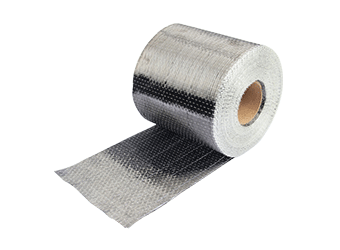

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.