Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

The new prestressing force can eliminate or slow down the stress lag phenomenon of the post-added members, so that the post-added members can effectively participate in the work of the original members, thus effectively reducing or even eliminating the phenomenon of strain lag of CFRP laminate, and achieving better reinforcement effect.

The construction process of HM pre-press FRP laminate for bridge.

Location and paying off

First, position and alignment for carbon fiber strip and anchor devices.

Drill hole

Then drill holes and polish the concrete surface in designed position.

Grooving

Slot along the both ends of the anchor devices, the groove depth is about 3cm.

Repairing and leveling

Repair the groove with repairing adhesive and polish after adhesive curing.

Planting anchor

Implant high-strength chemical bolts or high strength mechanical anchor bolt, anchor bolt level is not lower than 8.8 grade.

Instalingl bounding box

Install bounding box on the both sides and place in with anchor devices, keep the agreement on both ends of the centerline and fixed.

Install anchor box

Make sure that the tensioning and anchor block can slide freely within the bounding box.

Cutting carbon fiber laminate

Reserve 5 to 10 cm at the edge when cutting the carbon fiber strip.

Fixing carbon fiber laminate

Put the carbon fiber strip into wedge-shaped hole of tensioning and anchor block. Slid anchor block to starting position and fix tightly with fixture.

Fix jacketing and high strength anchor bolt

Assemble high-strength anchor bolts, gaskets, nuts, stop jack in tensioning end and adjust a tight top. Mike sure the stress direction of jack coincide with the centerline of the carbon fiber strip.

Prestreching

Make suitable protection to ensure safety of the construction and start pre-tension.

Apply epoxy resin adhesive

Apply epoxy resin adhesive on the surface of carbon fiber strip after uploading the pre-tension.

Prestress streching

Formal tensioning step by step, keep stress for 3 to 5 minutes, for every level tensioning and record the tensile strength and elongation. Then step to next level tensioning.

Removing the thread rod

Tight nuts after finished tensioning. Unloading jack, remove extra screw bolts.

Tablet fixing

Every 2 meters installed a tablet for slight pressure.

Fish product protection

The last step, make protective treatment of anchored devices and carbon fiber strop with anti-fire and anti-corrosion coating.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

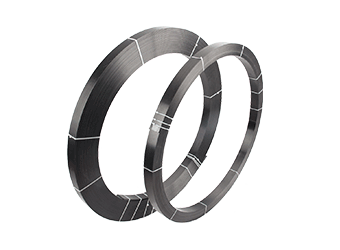

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.

O adesivo laminado de fibra de carbono Horse HM-120CP é um adesivo de base epóxi de componente duplo com forte resistência de ligação, resistência ao cisalhamento e resistência antienvelhecimento. É um epóxi usado para unir laminados de fibra de carbono pa