Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

As the new favorite of reinforcement technology, prestressed carbon fiber plate system, by actively applying prestress to concrete structural members, has achieved the effect of improving structural bearing capacity.

When it comes to prestressing, the first reaction of many engineering people is to use prestressed steel wires, steel strands and prestressed rebar. In fact, the application of carbon fiber materials in prestressed concrete structures is also slowly being promoted.

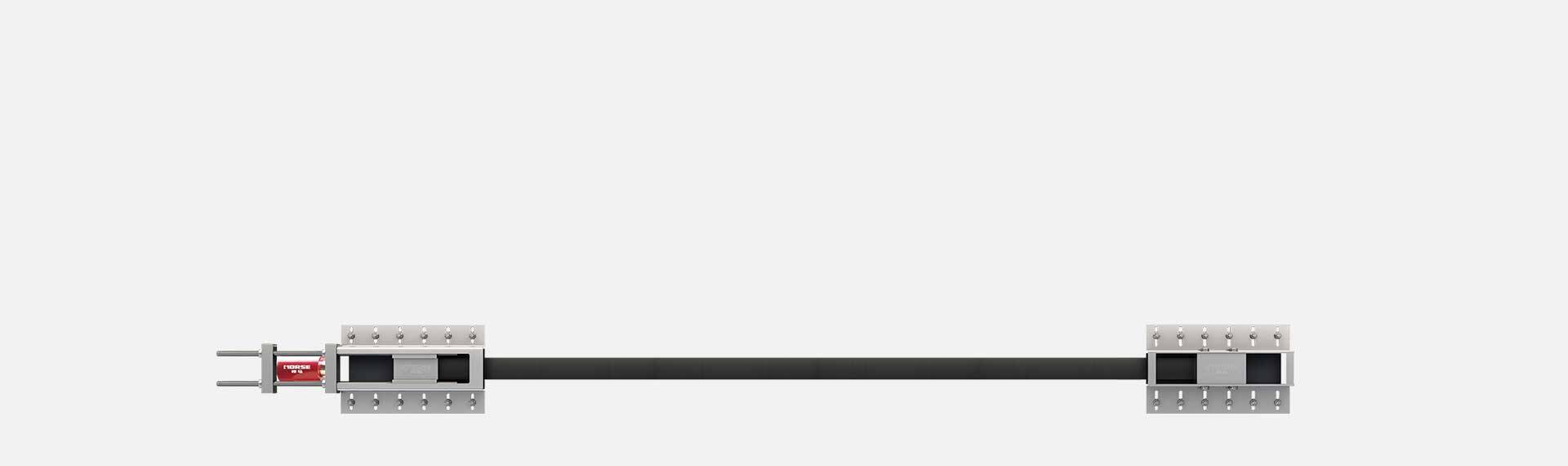

In the field of structural reinforcement, there is also a combination of prestressing and carbon fiber materials. An active reinforcement technology is to apply prestressing technology to carbon fiber boards to form a high-performance prestressed carbon fiber board reinforcement system. Generally composed of prestressed carbon plate, supporting structural glue, anchoring system, tensioning system and other parts.

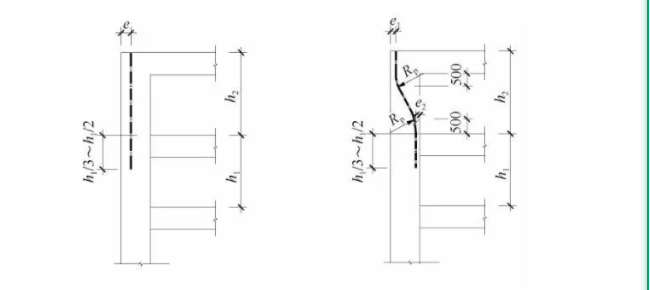

Principle: The carbon fiber plate is bonded to the concrete member by epoxy adhesive, the carbon laminate is tensioned, the prestress transmission is completed through the anchoring unit and the structural adhesive, forming a new load balance with the structure, and improving the structural bearing capacity.

Scope of application

1) Bridge structure reinforcement

Small and medium-span bridge flexural reinforcement, including T-beams, hollow slab beams, small box beams, box beams, etc., is especially suitable for bridges with many transverse cracks in the mid-span or excessive deflections in the mid-span.

2) Industrial and civil construction reinforcement

Bending reinforcement of long-span beams or floor slabs, prestressed reinforced concrete beams and slabs, prestress loss compensation, etc

Prestressed CFRP plate system advantages

1) The structure does not hardly increase the weight after reinforcement, and the carbon fiber board used has the characteristics of light weight, high strength and aging resistance.

2) Improve the strength utilization of carbon fiber materials, and change passive reinforcement to active reinforcement. The carbon fiber board has a larger strain before the second stress, thereby effectively reducing or even eliminating the phenomenon of strain lag of the carbon fiber board, and achieving a better reinforcement effect.

3) Increase the rigidity of the component, reduce the deflection of the original component, and improve the performance in the use phase. The reverse bending moment generated by the prestress can offset part of the impact of the initial load, improve the bearing capacity in the use phase, reduce the original crack width in the component and even close it, and limit the occurrence of new cracks.

4) The durability of carbon fiber board material is much better than steel, and the maintenance cost is very low.

Summary: As the new favorite of reinforcement technology, prestressed carbon fiber plate system, by actively applying prestress to concrete structural members, has achieved the effect of improving structural bearing capacity.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

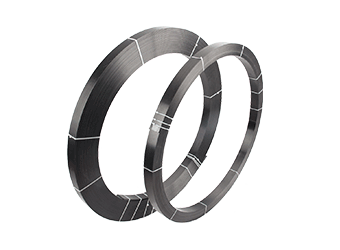

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.

O adesivo laminado de fibra de carbono Horse HM-120CP é um adesivo de base epóxi de componente duplo com forte resistência de ligação, resistência ao cisalhamento e resistência antienvelhecimento. É um epóxi usado para unir laminados de fibra de carbono pa