Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

The pultrusion process is also an important factor affecting the performance of carbon fiber laminate. The pultrusion process is first related to the machine used for pultrusion. It is also necessary to pay attention to whether each strand is straight during the pultrusion process. The slackness of the strand will cause the carbon plate to be unevenly stressed, resulting in substandard tensile strength.

With the continuous increase of existing buildings, structural reinforcement has become an indispensable part of the construction industry. Whether the structure needs to improve its bearing capacity due to functional changes, or seismic reinforcement is inseparable. The reinforcement material used in structural reinforcement directly affects the quality of reinforcement from the source. Poor quality reinforcement material will reduce the reinforcement effect and even cause reinforcement failure, affecting the safety performance of the structure.

Among the many reinforcement methods, carbon fiber reinforcement has gradually gained more and more recognition due to its advantages such as simple construction, flexible operation, and obvious improvement of bearing capacity. It has become one of the most commonly used reinforcement methods. Carbon fiber is widely used and has a profound impact on structural safety. In order to ensure structural safety, high-quality carbon fiber must be used to avoid safety risks when selecting carbon fiber. We have introduced the selection method of carbon cloth, and today I will introduce how to distinguish the advantages and disadvantages of carbon laminate.

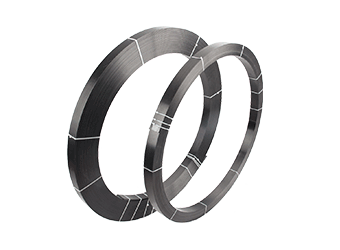

Raw material

Carbon fiber laminate is pultruded from carbon fiber precursor in epoxy adhesive, and the quality of carbon fiber precursor has fundamentally affected the performance of carbon fiber board. From a tow point of view, the tow used for the carbon fiber board used for structural reinforcement is a 12K tow, and the carbon board requires a carbon fiber content of ≥65%.

Except for the difference between tow and fiber content, carbon fiber precursors have different strength categories as carbon plates. According to the survey, the carbon fiber board uses two types of raw yarns, T300 and T700, with strengths of 3,530 MPa and 4,900 MPa, respectively. The requirements for the strength of the high-strength Class I carbon plate in the code is 2400MPa. It seems that the strength of T300 can meet the requirements of the high-strength Class I, but this is not the case.

Regardless of the pultrusion process or the content of the raw silk, the strength of the carbon fiber raw silk after pultrusion into a carbon fiber board will be reduced, and the reduction is obvious. Horse adheres to the use of T700 carbon fiber precursors, and through continuous technical improvements and innovations, the strength of carbon fiber boards has been increased to more than 2800MPa. From the perspective of strength requirements and safety reserves, carbon cloth woven from T700 raw silk is undoubtedly a better guarantee.

Pultrusion process

The pultrusion process is also an important factor affecting the performance of carbon fiber laminate. The pultrusion process is first related to the machine used for pultrusion. It is also necessary to pay attention to whether each strand is straight during the pultrusion process. The slackness of the strand will cause the carbon plate to be unevenly stressed, resulting in substandard tensile strength.

Quality inspection

Quality assurance is inseparable from product self-inspection and third-party inspection. Under the premise of ensuring the quality of the raw silk and the pultrusion process, the probability of defective products still exists in the production process of the carbon plate, so the internal self-inspection work is particularly important. The perfect self-inspection system and the resolute rejection of defective products are not put into use, which is the fundamental guarantee that the carbon fiber laminate can be used safely.

On the other hand, the third-party test report is also proof of the performance of the carbon fiber laminate. The third-party test report restores the true performance of the product through fair and impartial testing of the product.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.

Mantas de fibra de carbono unidirecionais Tecido de fibra de carbono unidirecional Mantas de fibra de carbono unidirecionais de alta resistência pré-saturadas para formar mantas de polímero reforçado com fibra de carbono (CFRP) usadas para reparar e forta