Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

Three days after the carbon plate was stretched, the deflection value of the flange plate and the bottom plate of each span decreased by 2mm, and the bridge beam plate as a whole arched upward. It indicates that the prestressed carbon plate has participated well in the structure's stress.

Disease:

After field inspection, cracks were found in the webs, floor and flanges of each span beam of the left and right bridges. The maximum width of the vertical cracks in the web is 0.40mm, and the maximum width of the central crack in the steel bar is 0.3mm. The maximum width of the transverse crack at the bottom of the plate is 0.37mm. The maximum width of the flange plate crack is 1.0mm.

Reinforcement scheme:

1) The prestressed carbon fiber plate is used to reinforce the flange plate of the beam. Seven pre-stressed carbon plates are arranged on the inside of the flange plate, of which four are long carbon plates (46m long), and three non-long carbon plates (edge span 10.18m, mid-span 13.6m). Five prestressed carbon plates are arranged on the outside of the flange plate, of which three are long carbon plates (46m long), and two are non-long carbon plates (side span 10.18m, mid-span 13.6m).

2) The prestressed carbon fiber plate is used to reinforce the bottom plate of the beam body. The bottom plate is arranged with 27 prestressed carbon plates with a pitch of 30cm. The length of the prestressed carbon plate is: 10.18m for side span and 13.6m for mid span.

Monitoring and effect:

During the bridge tensioning process, the tension value of each prestressed carbon fiber plate and the deflection value of each span are monitored. The bridge deflection monitoring is arranged at 6 points per span, one at each of the left and right flange plates, two at the bottom plate, and one each at 1/4 and 3/4 spans.

Three days after the carbon plate was stretched, the deflection value of the flange plate and the bottom plate of each span decreased by 2mm, and the bridge beam plate as a whole arched upward. It indicates that the prestressed carbon plate has participated well in the structure's stress.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

A fibra de carbono da Horse Construction é para reforço estrutural, reparo e modernização de substratos de concreto, alvenaria, aço e madeira em edifícios, pontes, rodovias, ferrovias, túneis, píeres e aeroportos civis.

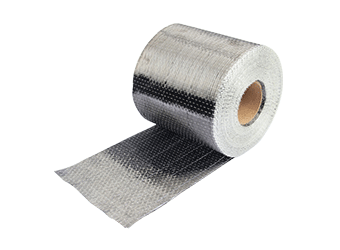

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.