Soluções

A Horse Construction oferece uma ampla gama de materiais de reforço estrutural, incluindo suporte técnico, suporte de documentação, suporte de produtos, suporte de software e suporte de projeto.

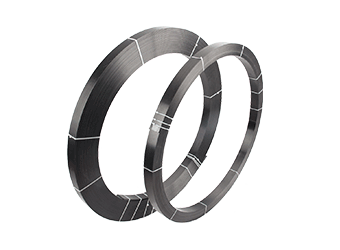

carbon fiber strip, structural strengthening

What is Carbon Fiber Strip structural strengthening systems?

The carbon fiber reinforced polymer(CFRP) strip system is based on carbon fiber strip and epoxy-based structural adhesive. Carbon fiber reinforced polymer (CFRP) strip is used for reliable high-performance structural strengthening systems. The carbon fiber reinforced polymer(CFRP) strip systems have been used successfully on thousands of projects worldwide. The carbon fiber reinforced polymer(CFRP) strip systems are widely used for bending and strengthening of buildings and other structures (such as bridges, beams, slabs and walls) under dynamic and static loading, to increase strength and increase long-term service life.

Horse Carbon Fiber Strip structural strengthening systems advantages

Durability tests have been conducted to ensure long-term performance and durability in different applications and environments.

Quick installation, short construction period, no additional equipment, cost savings

The application of externally bonded carbon fiber strip has no external influence, so there is no aesthetic influence.

Different sizes are available to suit different project requirements.

The combination of prestressed reinforcement system and CFRP strip forms a unique active external reinforcement solution.

Horse CFRP strip's Date Sheet

| Item | HM-1.2T Carbon Fiber Laminate | HM-1.4T Carbon Fiber Laminate | HM-2.0T Carbon Fiber Laminate | HM-3.0T Carbon Fiber Laminate |

| Thickness(mm) | 1.2 | 1.4 | 2.0 | 3.0 |

| Length(m) | 100 | 100 | 100 | 100 |

| Width(mm) | 50、100 | 50、100 | 50、100 | 50、100 |

Density(g/cm3) | 1.6 | |||

| Base | Carbon fiber reinforced polymer with an epoxy resin matrix | |

| Shelf Life | Unlimited (no exposure to direct sunlight) | |

| Color | Black carbon fiber laminate | |

| Tensile Strength | Mean Value | 3100MPa |

| Design Value | 2600MPa | |

| Modulus Of Elasticity | Mean Value | 165,000MPa |

| Design Value | 160,000MPa | |

Elongation at Break | 1.7% | |

| Thickness | 1.2mm, 1.4mm, 2.0mm, 3.0mm | |

| Temperature Resistance | >300° F(>150℃) | |

| Fiber Volumetric Content | >68% | |

| Density | 0.058 lbs./in 3 (1.6g/cm3) | |

Construction Process of Carbon Fiber Strip structural strengthening systems

1. Setting out according to design;

2. Remove painting of the concrete surface and polish, blow out the floating dust with compressed air;

3. Prepare adhesive: Mix component A and B evenly in bucket. Mix ratio by weight A: B = 2:1 ;

4. Installing: Paste the epoxy onto the surface of carbon fiber plate evenly, please avoid bubbles;

5. Anchorage: Paste the carbon fiber plate onto the concrete surface and fixed with steel strip, remove extra epoxy near the plate, and fix with steel framework;

6. Maintenance: Waiting for the epoxy to cure, curing time should be no less than 24 hours at room temperature.

Você pode encontrar tudo o que precisa aqui. Confie e experimente esses produtos, você vai perceber uma grande diferença depois.

O laminado de polímero reforçado com fibra de carbono Horse (CFRP) é um laminado composto pré-curado, colado na estrutura como reforço externo com epóxi HM-120CP.

O sistema de laminado CFRP protendido Horse (sistema CFRP pós-tensionado) inclui dispositivos de ancoragem e laminado de fibra de carbono especialmente projetados para pontes, edifícios e reforço de estruturas de aço.

O adesivo laminado de fibra de carbono Horse HM-120CP é um adesivo de base epóxi de componente duplo com forte resistência de ligação, resistência ao cisalhamento e resistência antienvelhecimento. É um epóxi usado para unir laminados de fibra de carbono pa